By

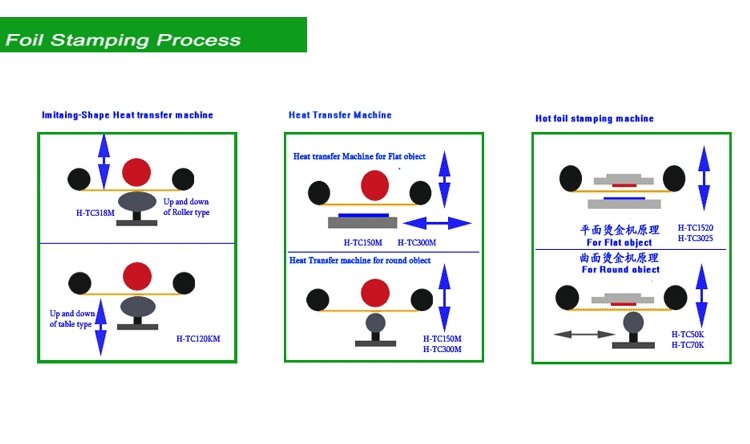

hot stamping machine

you will get metal gloss on your products; by heat transfer machine, you will transfer beautiful picture printed onto PET film to your products. It is consist of working table, hot press system, temperature controlling system, foil feed and rolling system.

l

Structure

Hot stamping machine and heat transfer machine have more complex structure than pad printer and screen printer:

1.

Working table: Install fixture and substrates. There are four kinds of working table: Flat stillness, round, flat shuttle and conveyer , flat stillness working table installed flat stamping machine. Round working table use to stamp round products and flat shuttle working table use to stamp flat products.

2.

Hot press system: Install silicon rubber plate or silicon rubber roller. Silicon plate used by hot stamping machine and silicon rubber roller used by heat transfer machine. When silicon plate or silicon roller press down and keep contact with substrate, heat and pressure pass through stamping foil or heat transfer film.

3.

Temperature controlling system: Measure silicon plate and silicon roller temperature and pass to controlling meter, keep nearest range between fact temperature and setting temperature so that get best quality.

4.

Foil feed and rolling system: Install stamping foil or heat transfer film. After stamping and transfer one product, the foil and film will rolling to equal length according to your setting rolling time.

5.

Operation controlling system: Most of stamping machine and heat transfer machine controlled by micro-computer built in to make machine stability and easy to operate. When testing, only press simple action key and when starting automatic key to begin printing will be helpful to operate screen printer.

l

Mainly factor

1.

Silicon plate and silicon roller:

Siliconplate adhered to upper of stamping machine; roller installed on the heat transfer machine. More harder silicon rubber get more better stamping quality

2.

Stamping foil and heat transfer film:

Stamping foil coloured made by vacuum braise-plating and heat transfer film printed by cave copper printing machine. Stamping foil used by stamping machine and heat transfer machine; heat transfer film only used by heat transfer film.

3.

Fixture:

It is important to make fixture according to products. Regular products need the fixture made by lathe or CNC. Complex products need the fixture made by polyester resin.

l

Sorts

1.

Flat stamping machine: Stamping head is flat and working table keep stillness named

Flat stamping machine(H-TC1520) . Conveyer working table installed on flat hot stamping machine named

conveyer hot stamping machine,There are two kinds of stamping machine: one is

Manual stamping machine(HM-TC3025), the other is

Air-controlling machine(H-TC3025).

2.

Cylinder stamping machine: Shuttle working table installed on flat stamping machine named C

ylinder stamping machine(H-TC70K) . Round products can be stamped by this kind of machine.

3.

Flat heat transfer machine: Stamping machine with silicon roller and shuttle working table named

Flat heat transfer machine(H-150M) . When roller press down to contact flat substrate and working table move from left to right, flat products will be transferred through heat and pressure.

4.

Cylinder heat transfer machine: Round fixture installed on the working table , cylinderproducts will be transferred. Most of heat transfer machine have two function: when transfer flat product, removing round fixture and make working table movement ; when transfer cylinder product, installing round fixture and keep working table stillness.

5.

Imitating-surface stamping machine(H-TC120KM)

: Stamping head can be fluctuated when contacting with product surface figure because of fluctuating device. Oval object, camber object, ball object etc complex product will be transferred by this machine. With the development of market,

Fully-automatically cylinder stamping machine

improve rapidly stamping speed and enter into the vision.