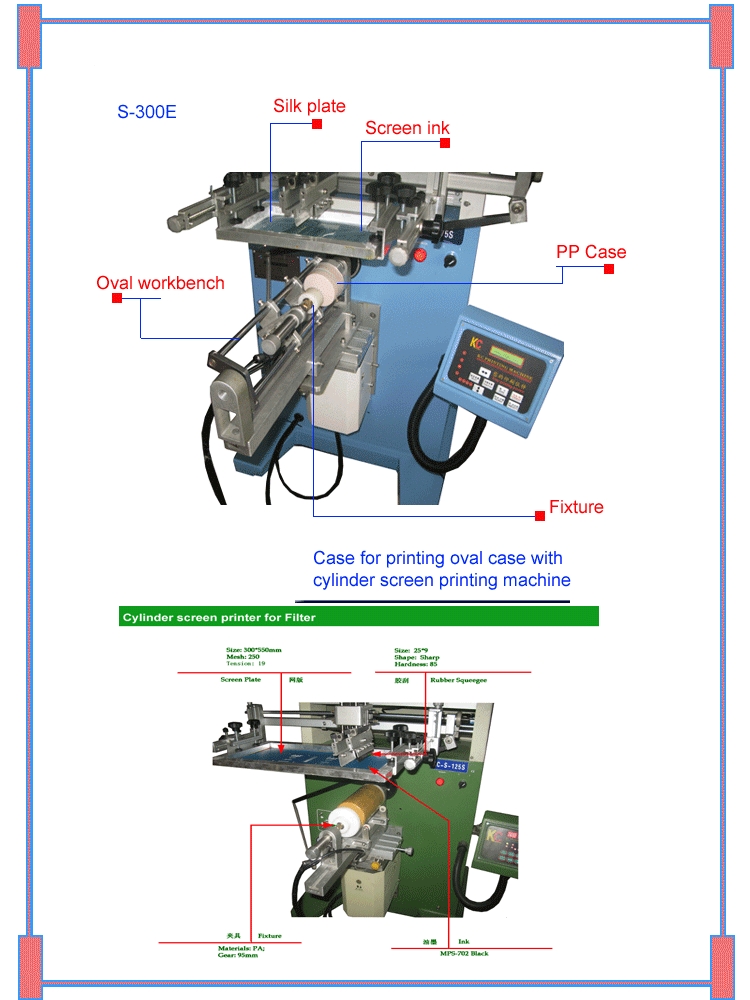

Cylinder screen printer for cosmetic jars

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.

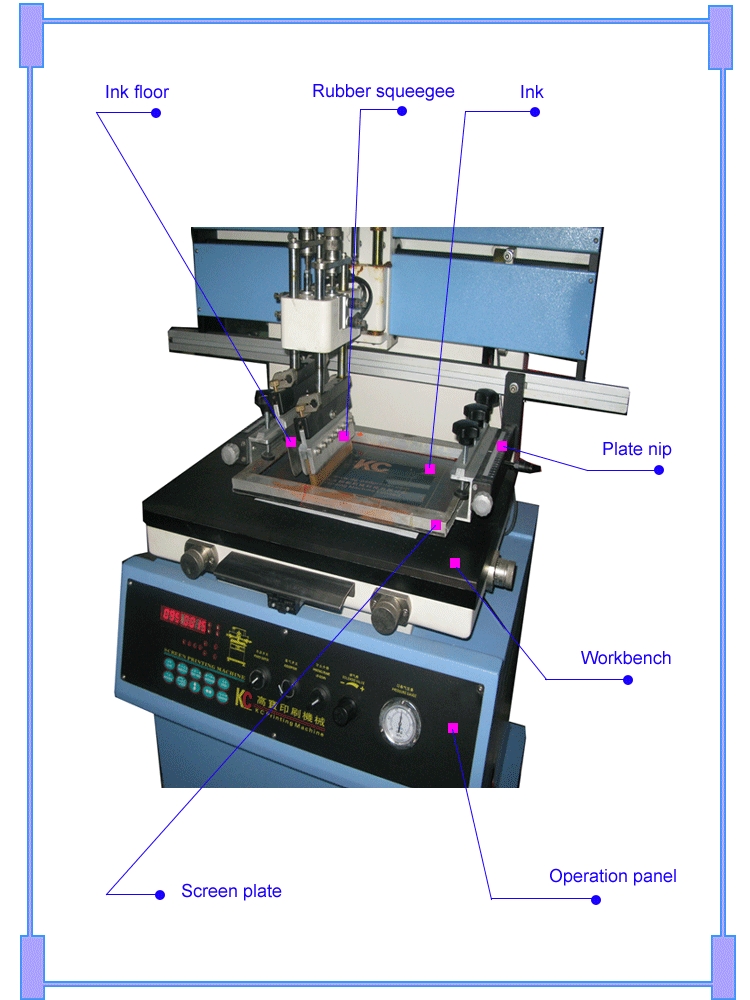

Vacuum plain screen printing machine

The products that humans make most are probably planar or nearly planar. From the screen printing process, there is no difficulty in printing flat products. The product is placed on the workbench, the screen is installed, the screen falls, and the scraper moves to complete the screen printing. What you need to know is:

Screen - what kind of pattern you want to print, you need to make what kind of screen, each screen can only use one color, if you change the color, the screen will change accordingly, if you want to register colors, you need to use multiple screens .

Ink—The reason why silk screen printing is ubiquitous is that you can choose a variety of inks that match the material. According to the current development of ink technology, you can find corresponding inks for almost every material.

Fixtures - Paper and film do not require any fixtures, but some injection molded products still require fixtures. Therefore, the main form of the screen printing machine workbench is the screen printing machine designed for the need for fixtures and the need for fixtures. On the automatic flat screen printing machine, the fixture is more important, and its positioning function directly determines the position accuracy of the screen printing.

Squeegee - Square squeegee is most commonly used in flat screen printing. Different products require squeegee with different hardness or even special shape. In those high-precision screen printing technologies, the choice of squeegee becomes particularly important.

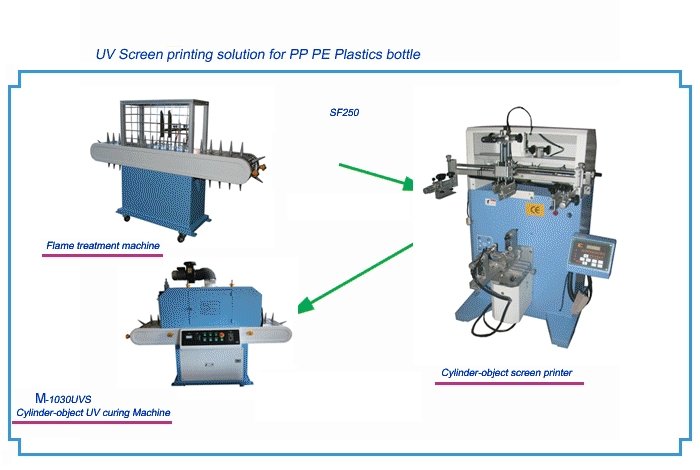

Cylinder Objects UV screen printing solution

In the plastic packaging industry and cosmetic packaging industry, polyethylene and polypropylene materials are widely used due to their excellent processing ability and chemical corrosion resistance, which has also become a problem that the silk screen printing process must face.

The chemical resistance of polyolefin materials is a weak point for printing, which means that it will reduce the adhesion of ink. The current effective method is to use flame treatment, which can pour oxygen atoms on the surface of polyolefin materials 2. Weaken its non-polarity, thereby improving the adhesion of the ink

For the screen printing process, if the ink is selected correctly and the flame surface treatment is used, the adhesion of the ink will be significantly improved, which will increase the attractiveness of the product itself to users.

UV ink is especially commendable in terms of packaging in the cosmetics industry, because when you choose cosmetics, you are likely to be interested in the high gloss of the ink, mainly due to the gloss of the acrylic resin in the UV ink after curing. Now The use of ink in cosmetic packaging has increased to more than 85%.

Another remarkable feature of the ink is that it must be irradiated by UV lamps to dry, so it is basically in a flowing state on the screen, and the situation of blocking the screen will basically not happen. This is the convenience of the operation, so when With the silk screen printing process, a curing machine with a curved surface must be selected. A single flame processor, curved screen printing machine, and UV curing machine constitute a complete solution for UV curved screen printing, but due to the interruption of the process, it is difficult to increase the printing speed, and the constraints of each link also restrict the technical ability of the operator.

In recent years, the fully automatic hollow container bottle screen printing machine has been popular in the market. It integrates many processes such as automatic feeding, flame treatment, curved surface screen printing, UV curing and automatic unloading, etc., with fast speed, stability and few quality constraints. , has gradually seized the market occupied by semi-automatic printing, and has first been popularized in western developed countries and some large cosmetic factories.