With the development of the Chinese market, fully automatic silk printing technology has gradually been recognized. This is not only the objective reason for the reduction of profit margins in market competition, but also to a large extent that China must enter the era of technology competition.

There are two main forms of automatic screen printers: straight transmission type-that is, the form of screen printing dragon, which is a transmission form that connect monochrome screen printers and perform program control. The straight-line transmission type is an open structure, which is suitable for printing large bottles. The body, but its transmission route is long, and the curved body needs to be connected to the working location one by one. Therefore, the stability is not particularly good.

The linear transmission screen printer is suitable for the printing of the hollow bottle, and there are multi -color printing and monochrome printing at the bottom. For the oval curvped face bodies, its advantages are more obvious. Silk printing decoration.

The disc transmission type is uniformly arranged around a large set of screen printing devices around a large disc, which is very suitable for printing insert type curved surfaces, such as cosmetics bottle, hose, etc. Driven by the shaft, enter the working position, so the transmission is more stable, and the cover is more accurate. However, the disk transmission structure is too closed, it is not suitable for larger curved surfaces, and it is not suitable for hollow curved surfaces.

Taper Silk mesh printing machine

The full -automatic screen printing machine is now impossible to print the cone. The curved body that is large and highly required for printing accuracy should be printed with a pyramid. Fan fan type will be formed on the surface of the online version instead of rectangle like cylindrical body. The design principle of a traditional cylindrical screen printer is not suitable for the cone. To ensure that the mother line of the cone is always pure with the online version of the online version, which is purely pure with the online version. Rolling, the transmission structure of the screen printer must also ensure that the line speed balance of the fan type and small segments must be ensured at the same time.

Half -automatic cylindrical silk screen printing machine

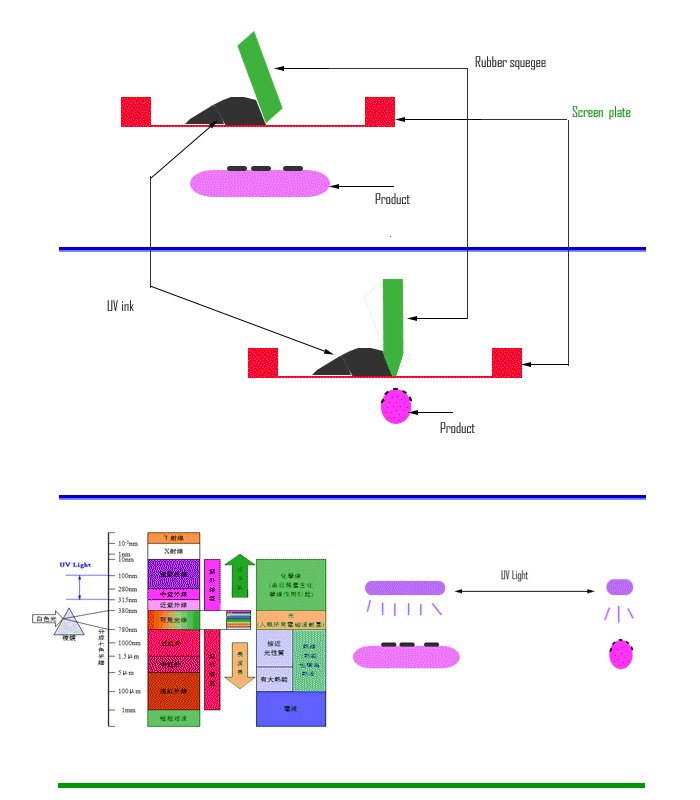

Because the cylindrical body in the mold manufacturing of plastic packaging is the simplest, the most important thing is the width of the cylindrical packaging bottle, so the semi -automatic cylindrical screen printer is the most common. When the line is rotated, the bus is always in contact with the line -cut line. Record the information on the bus to record the information on the surface of the cylinder. The rules that are generally observed in the instrument.

Silk prints with positioning holes

Generally speaking, the curved screen printer of the cylindrical body only needs to solve the problem of rotation of the curved body, but this is often for a color. If it involves the colors, we must find the starting point of the second color, or in other words, or in other words Ensure that the curved body is kept in the same position when the seal is seal. There are two types of curved surfaces: one is marked in the direction of the circle, such as the handle of the tea cup, the insertion of the ballpoint pen, the reinforcement of the flashlight, etc. This part of the body just constitutes the positioning point. As long as the necessary design is made next to the web version, you can solve the problem of the title. The other is that the plastic bottle that cannot be made by the handle is usually designed at the bottom. Some of the positioning holes. The design of the positioning hole at the bottom of the bottle as a standard is actually considering the wire printing process. In fact, there is a wire printing of the curved surface of the positioning hole. Because the contraction rate of the plastic itself is very uniform, especially the contraction rate is large, the stability is not stable Good PP PE bottle. Require high curved body to make modified PC PETs. However, most bottles do not require particularly fine printing effects. We don't have to consider this problem too much.

There is no positioning point.

Many curved body itself does not design positioning holes, and hose curved surfaces are not allowed to have positioning holes. It is more troublesome to use semi -automatic cylindrical wire printer to print colors. The ideal method is to choose the curved cylindrical body. The color of the printing of the photoelectric sensor of the printing of the printing of the printing machine must be printed with the overall transfer method of the fixture. The workbench is accurate to ensure that the cover is accurate.

As a remedy measure, such as the original printed monochrome bottle, you need to print a color to increase the freshness, and the number is not very large. You can consider paste the printing logo point at the specified location to complete the colors. Of course, this is a very rough approach. , The accuracy of the pumping is not too high.