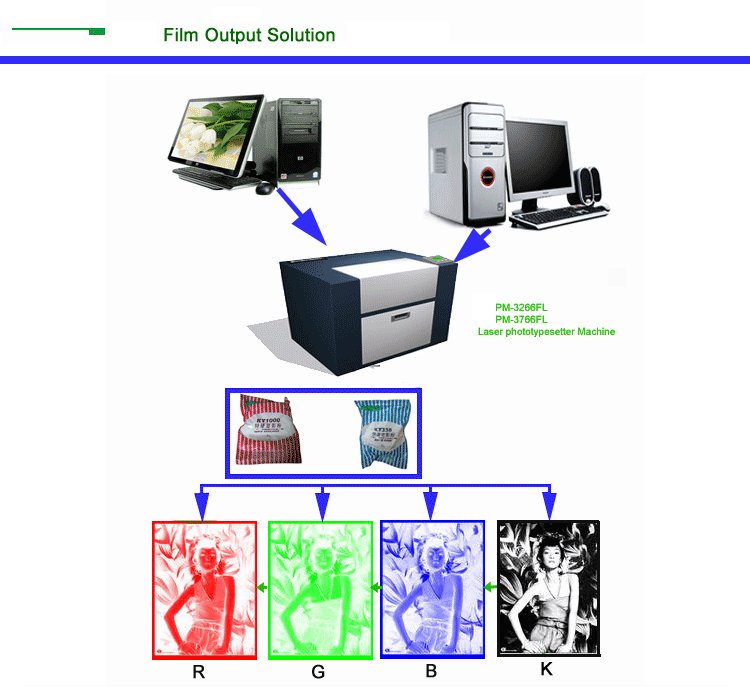

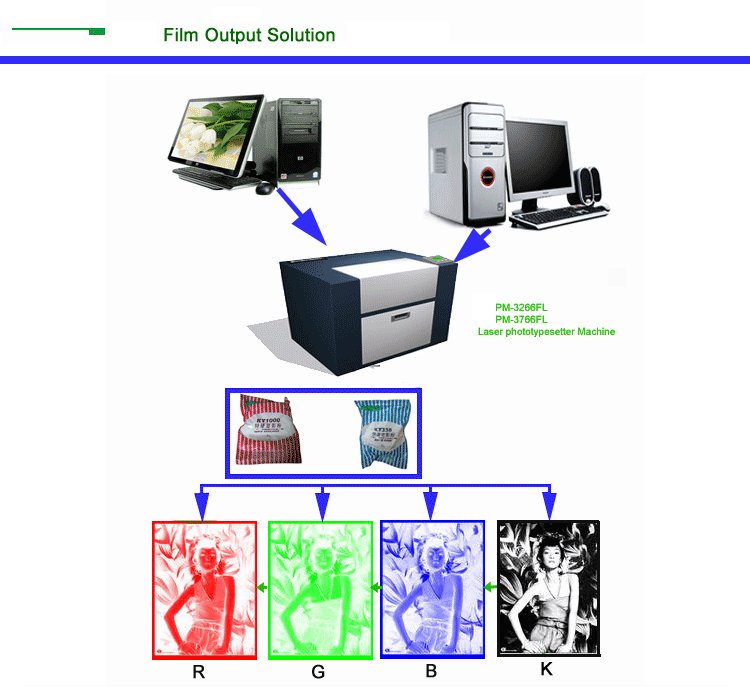

Exposure to the sun tied the film to fit the plate substrate on the UV sunshine machine on the exposure, through the backplane production model is the basic process of traditional printing methods. The mainstream printing industry has entered the print industry, printing, silk screen and bronze and other special printing industry is still staying in the traditional plate of stage. In recent years, many printed equipment manufacturers try to use different processing equipment to improve the plate production process, and constantly cut the government's increasingly environmentally friendly policy, while also significantly cut the traditional process of the preparation of the traditional process of the process: for example, the use of automatic etching equipment corrosion steel sheet, using laser engraving machine carved steel and bronze gold, the use of CTS directly to create network and so on. These advanced technology expansion despite the favor of many users of the favor, but to go into the popularity, but also have a long way to go. Exposure method making plate prints can not quickly swap into historical waste, for many small micro-enterprises using traditional plate methods in the long time in the relatively long time is still necessary. It is well known that the films used in the process of paper are usually output with laser lighting, while the laser lighting is expensive, small and medium enterprises are difficult to buy, but to the nearby professional Four output center to output, design and modify the control will waste a lot of time. Especially some stationery, toys, gifts, auto parts, electronic products, templates often replace, printing pictures need to change according to customer needs, which for the fast delivery and reaching the instantaneous intention of the customer is very difficult. A ladder-sided specially designed for small and medium enterprises will be generated.