Construction sites, heavy machinery factories and some occasions where there are falling objects, motorcycle drivers are required to wear helmets for protection. The decoration of safety helmets is a problem that printing practitioners often encounter. So how is the helmet decorated? Through a simple survey of industry personnel, it can be found that safety helmets can be decorated by pad printing, silk screen printing, bronzing, thermal transfer printing, water transfer printing, labeling, etc. Pad printing is the most mature and common decoration process. The reason is that pad printing is very suitable for products such as safety helmets with irregular shapes and fixed printing positions, and it is also very easy to realize mechanized operation.

Monochrome pad printing

Some helmets only require a single-color logo to be printed on the forehead of the helmet. This is a relatively simple color. As long as it is a single-color pad printing machine, it can basically meet the conditions. All you have done is how to make the jig that holds the hard hat in place.

Multi-color pad printing

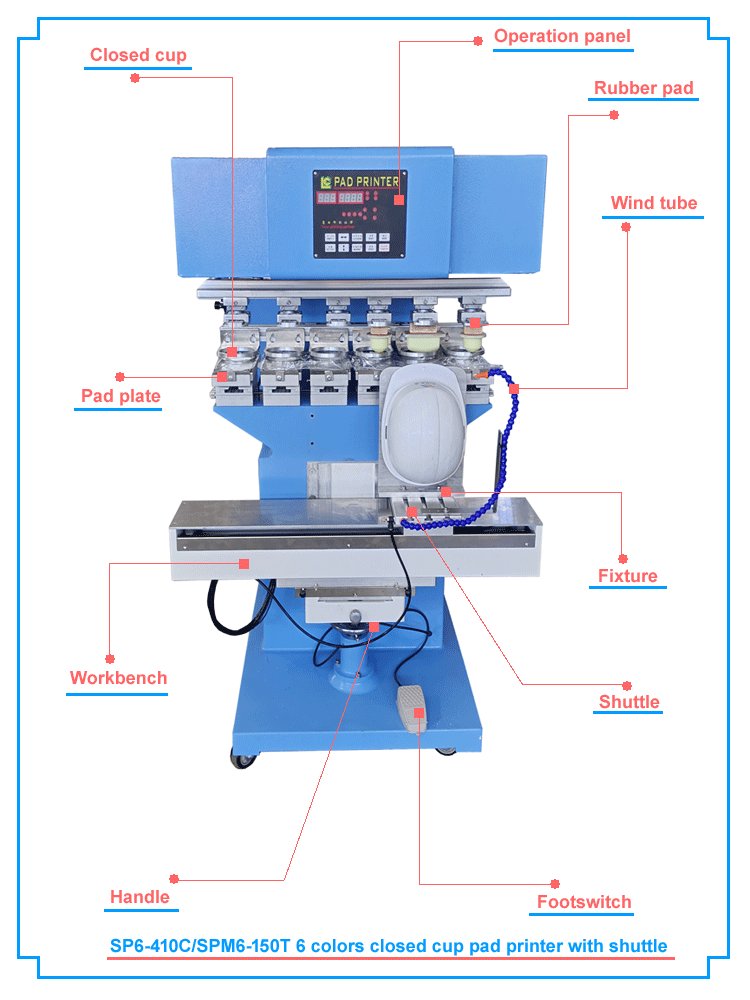

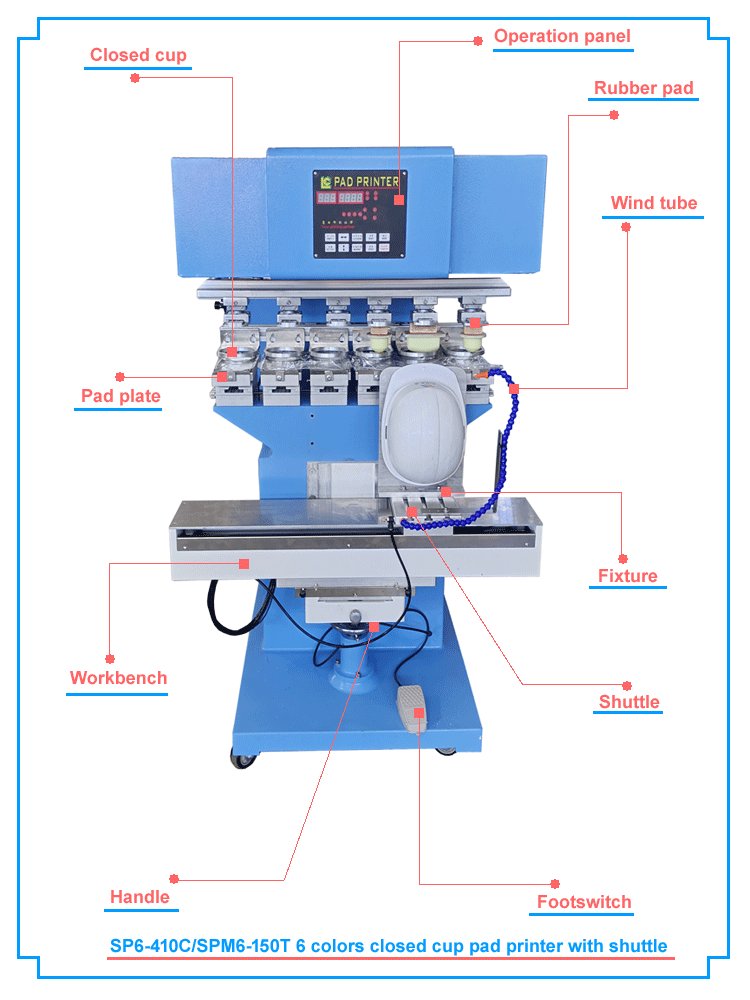

More hard hats require multiple colors to be printed on the forehead, which is why you need to choose a shuttle-type multi-color pad printer. The reason why we choose a shuttle-type pad printing machine is that, in addition to the high overprinting accuracy, the shuttle-type pad printing machine also accommodates a relatively large size of the product, and the size of the safety helmet is relatively large. The turntable type pad printing machine cannot fit such a helmet. The multi-color same-position pad printing process is not complicated, and the pneumatic shuttle pad printer and servo shuttle pad printer can easily meet the requirements.

Multi-color pad printing at different positions

A considerable number of safety helmets are not only printed on the forehead, but also printed on the back, sides and even more irregular positions of the hat, so it is difficult for ordinary shuttle pad printing machines to meet the requirements, you must customize one. The multi-color shuttle pad printing machine with a servo rotating device on the worktable, considering that some large companies have high requirements for the printing accuracy and position accuracy of the safety helmet, it becomes necessary to use the full servo motor control for the pad printing machine.

The pad printing machine controlled by servo motor can accurately control the front and rear, left and right, up and down, and angle according to the printing position of the safety helmet, so it has been widely used in many high-demand pad printing machines in recent years.

In addition to the servo rotating device of the worktable, the control of the printing angle of the rubber head also tends to be servoed. For some electronic products, toy products and kitchen utensils, the printing position is very special. In addition to the multi-angle rotation of the fixture, the multi-angle rotation of the glue head will greatly improve the production efficiency.