High in the air and underground construction workers, mining workers need to wear safety helmet, which is the most basic safety operation regulation.

The most common safety helmet front and side printing LOGO printing form, in addition to screen printing process is relatively rough, the vast majority of enterprises to adopt the pad printing technology, there are individual enterprises to use water transfer printing technology.

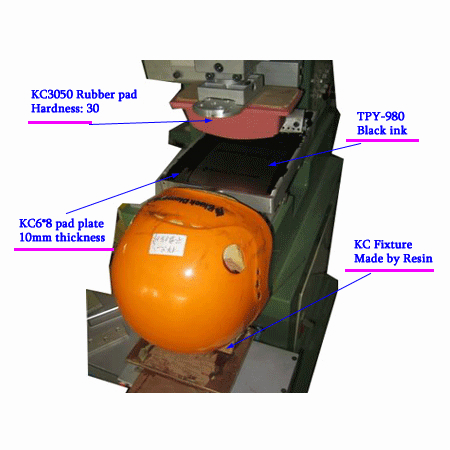

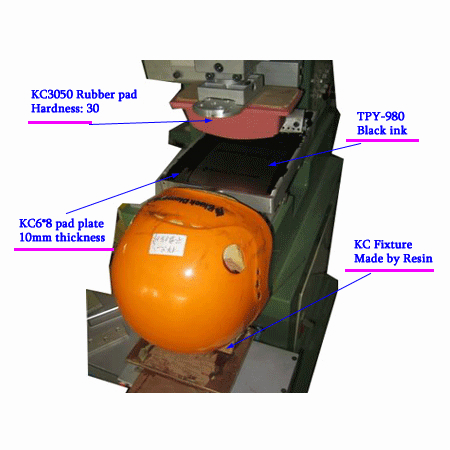

Dimensions of the safety cap is relatively large, but the printing area is usually very small, in the choice of printing machine as long as the pad printing machine stroke be enough. The second is to use suitable for unsaturated polyester resin material ink.

Safety helmet monochrome pad printer

• Principle: The ink is transferred from the printing plate to the surface of the safety helmet through the pad printing head to realize the printing of patterns or texts.

• Structure: It is mainly composed of printing plate, pad printing head, scraper, ink system and workbench.

• Advantages: The equipment is relatively simple and easy to operate, suitable for printing safety helmets with low color requirements and simple patterns.

Safety helmet four-color shuttle pad printer

• Principle: The shuttle workbench is used to move between four different color printing plates and pad printing heads to realize four-color overprinting.

• Structure: In addition to the basic pad printing parts, there are also shuttle workbenches, four independent ink systems and corresponding positioning devices.

• Advantages: It can print colorful patterns with high overprinting accuracy, which is suitable for the production of safety helmets with certain color requirements.

Safety head servo rotary pad printer

• Principle: The helmet is driven to rotate by the servo motor, and the pattern is printed with the pad printing head, which can realize multi-sided printing.

• Structure: including servo motor, rotary table, pad printing head, ink system, etc., the structure is relatively complex.

• Advantages: can print on multiple sides of the safety helmet, good flexibility, high printing accuracy.

High-precision touch screen multi-axis servo rotary pad printer

• Principle: adopt multi-axis servo system to control the rotation of the helmet and the movement of the pad printing head, and operate and set parameters through high-precision touch screen.

• Structure: there are multiple servo motors, high-precision transmission mechanism, complex pad printing parts and advanced control system, etc.

• Advantages: extremely high printing accuracy, convenient and intuitive operation, can meet the production needs of safety helmet printing quality and accuracy requirements.