Plastic buckets with a diameter of more than 250mm are commonly used to hold chemical products such as paints, coatings, lubricants, and hydraulic oils.

The common practice in the brand performance of makeup products is to perform printing decoration. Currently, there are many ways to decorate large-diameter plastic buckets:

1) Silk screen

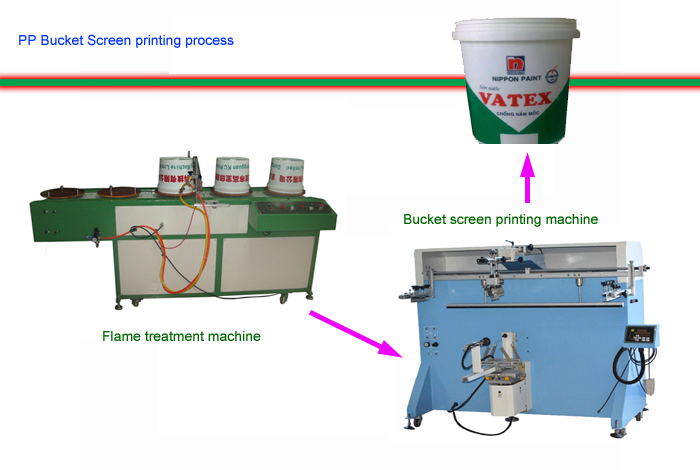

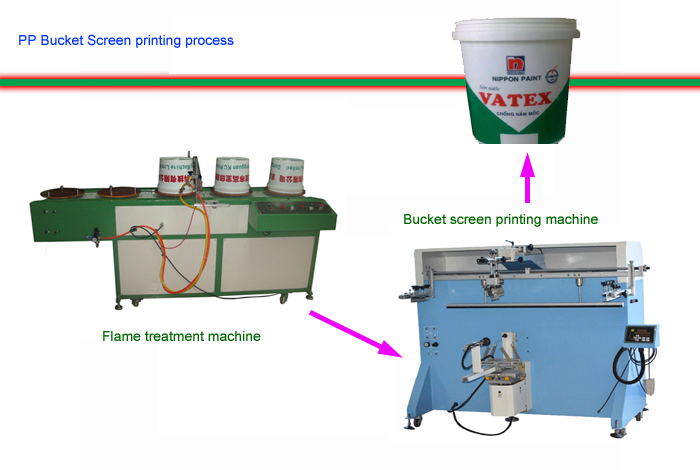

As a common method of screen printing, a semi-automatic curved screen printing machine can be used for one color and one color printing, and a full-automatic plastic barrel screen printing machine can also be used for one screen printing. Semi-automatic investment is relatively small, a flame processor, a curved screen printer and a UV curing machine can be. Automatic screen printing machine is a collection of flame processing, multi-color screen printing, UV curing lamp technology, and the screen printing machine is bulky and expensive.

2) Thermal transfer

The thermal transfer method has recently developed rapidly. Since the thermal transfer film can be realized on a high-speed gravure printing press, it is easier to realize the decoration of the tone color and the printing is more exquisite. Most of the plastic barrels have a certain degree of taper. The automatic heat transfer machine with fan-shaped track and the beautiful design of gravure printing make the decoration of plastic barrels dazzling. Thermal transfer and screen printing machines occupy a large market share, but due to their slow speed, they also restrict their development.

3) Offset printing

Flexo printing has always been known for its high speed. Although its print quality and screen printing are slightly inferior to those of thermal transfer, its excellent production efficiency is unmatched, and it occupies a leading position in large-scale plastic bucket manufacturers.