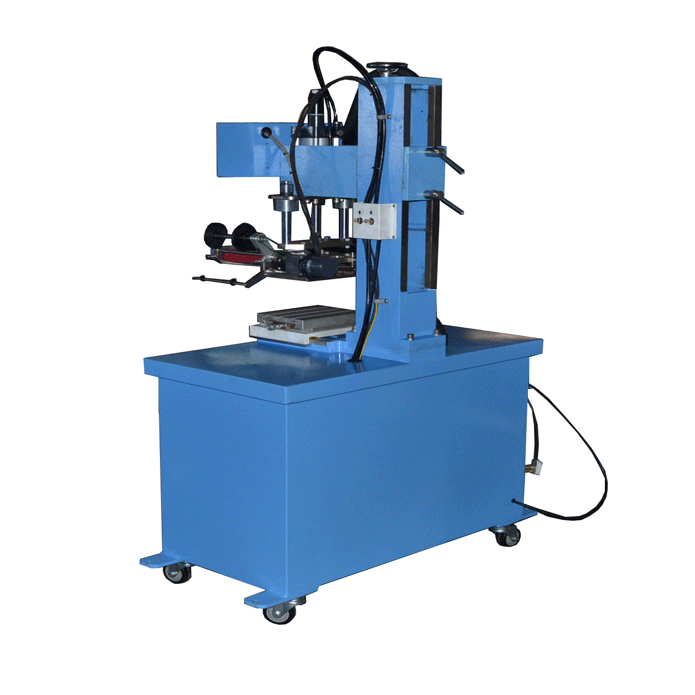

Model No.︰H-TC200

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 1779 / pc

Minimum Order︰1 pc

Soap box cosmetic box flat pneumatic hot stamping machine:

Structural composition

• Hot stamping head: It is the core component of the hot stamping machine, usually made of metal material, driven by a cylinder-driven lever mechanism. When the lever becomes a straight line, the pressure reaches the maximum. A heating element is installed inside the hot stamping plate, which can quickly heat up to the required hot stamping temperature.

• Pneumatic system: It includes cylinders, solenoid valves, etc. Compressed air controls the movement of the cylinder through the solenoid valve, thereby driving the hot stamping head to move up and down to complete the hot stamping process.

• Temperature control system: It is mainly composed of temperature sensors, controllers and heating elements. The temperature sensor monitors the hot stamping head temperature in real time. The controller adjusts the power of the heating element according to the difference between the set temperature and the actual temperature to keep the hot stamping head temperature in the appropriate range.

• Workbench: It is the place where the fixture and soap boxes, soap boxes, and cosmetic boxes are placed. Semi-automatic hot stamping machines use manual methods to place products, and the hot stamping is completed and removed manually. The workbench can be adjusted in front and back, left and right, and angle to ensure the correct hot stamping position.

• Hot stamping foil rewinding device: Driven by the motor, the hot stamping foil can be conveyed to a certain length according to the set time. The larger the hot stamping pattern, the longer the hot stamping foil is conveyed.

Working principle

Place the soap box, soap box, cosmetic box, etc. on the fixture of the workbench. After starting the machine, the hot stamping head is pressed down and fits tightly with the top of the packaging box. At the same time, the temperature control system makes the hot stamping head reach the set temperature. The metal foil or pigment on the hot stamping paper is quickly transferred to the surface of the packaging box under the action of high temperature and high pressure, forming a beautiful hot stamping pattern or text. After the hot stamping is completed, the hot stamping head is lifted to complete a hot stamping process. This cycle achieves continuous and efficient hot stamping operations.

|

H-TC200 Pneumatic hot stamping Machine//Structure |

||

|

Working table |

High strength Steel plate , size:200*250mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Stamping plate size |

150*200mm. |

|

|

H-TC200 Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

H-TC200 Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC200 precision hot stamping Machine

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

||

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

H-TC200 Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|