Model No.︰M-1030UVS

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 3794 / pc

Minimum Order︰1 pc

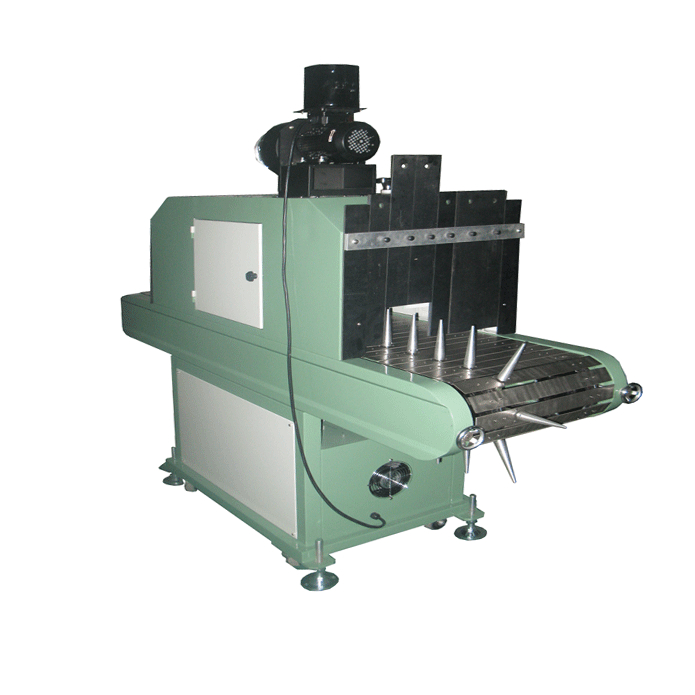

UV curing machine for cylindrical bottle products:

Working principle

The UV curing machine mainly uses the energy of ultraviolet rays (UV) to make the UV coating, ink and other materials coated on the surface of the bottle cylinder undergo polymerization reaction, thereby quickly curing. During operation, the bottle is fixed and rotated by a rotating fixture, which can ensure that the entire cylindrical surface of the bottle can be evenly exposed to the ultraviolet rays emitted by the UV lamp. Under the conveyance of the stainless steel conveyor belt, the bottle passes through the UV lamp area at a uniform speed, so that the surface coating is quickly cured under the irradiation of ultraviolet rays.

Structural features

• Bottle rotating fixture:

• This fixture can firmly fix the bottle and allow the bottle to rotate around its own central axis. During the curing process, the rotation of the bottle ensures that the ultraviolet rays can be evenly irradiated to every part of the bottle cylinder to avoid incomplete local curing. For example, for the curved bottle surface, rotation can make the UV coating evenly distributed under the action of gravity, thereby improving the curing quality.

• Stainless steel conveyor belt:

• The conveyor belt made of stainless steel has good corrosion resistance and wear resistance. It can stably convey bottles, ensure that the bottles move at a uniform speed during the curing process, and make each bottle receive UV irradiation for the same time, which is conducive to ensuring the consistency of the curing effect. At the same time, the stainless steel conveyor belt is easy to clean, and even if a small amount of paint drips, it can be easily cleaned without affecting the normal operation of the equipment.

• Imported UV lamps:

• Imported UV lamps usually have higher UV output intensity and more stable performance. The UV wavelength range they emit is more accurate, which can more effectively excite the photoinitiator in the UV coating, making the curing reaction more rapid and thorough. In addition, the service life of imported lamps may be relatively long, reducing the trouble of frequent lamp replacement and improving the work efficiency of the equipment.

• Easy to operate and maintain:

• Operation: The equipment may be designed with a simple and easy-to-understand operation panel. The operator can control the bottle conveying speed, rotation speed, UV lamp power and other parameters through simple settings, which is convenient for adjustment according to different bottle sizes, paint types and other factors.

• Maintenance: The structural design of the equipment may be easy to maintain. For example, the UV lamp may be easy to disassemble and replace, and the cleaning and inspection of the conveyor belt is also relatively convenient. The rotary clamp may be rust-proofed and has a simple mechanical structure, a low probability of failure, and is easy to repair even if a failure occurs.

|

M-1030UVS Cylinder UV Drying Machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

M-1030UVS Cylinder UV Drying Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

M-1030UVS Cylinder bottle UV Curing Machine//Advantage |

|

|

Function |

|