Model No.︰SF250

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 2235 / pc

Minimum Order︰1 pc

The printing of polyolefin materials often encounters the problem of ink shedding. The main reason is that it is composed of non-polar molecules. The printer will first choose a special polyolefin ink. If the adhesion of the ink does not meet the requirements, then Consider pre-treating the product surface, and flame treatment is a common and effective method.

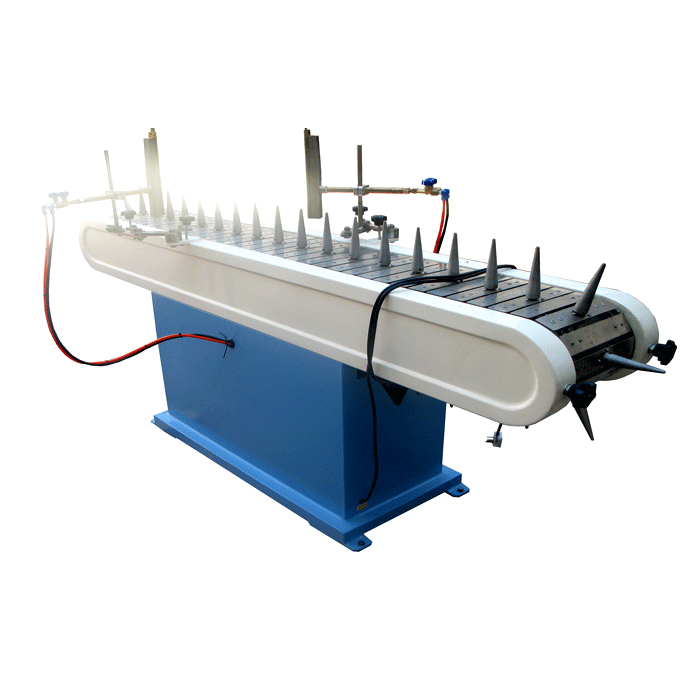

The most suitable products for flame treatment are some cylindrical plastic bottles, and the effect is satisfactory no matter whether solvent-based ink or UV ink is used. The flame treatment machine for plastic bottles is composed of a flame generating device and a conveyor belt. The conveyor belt is often equipped with a rotatable support cone. The bottle can be inserted into the cone and enter the flame treatment head with the conveyor belt. The inside of the flame treatment head is filled with compressed air and Combustible gas, after ignition, sprays out a flame with pressure, which can oxidize the surface of the bottle. For automatic screen printing machines, flame treatment devices have almost become a standard configuration.

1. Structural features

• Fully automatic vertical turntable structure: The turntable is one of the core components of the machine. It is placed vertically and surrounded by multiple workstations. This design can make full use of space and achieve efficient continuous production. The turntable is driven by a motor, and a precise transmission system ensures its stable and uniform rotation, providing an orderly workflow for the thermal transfer of plastic products such as cosmetic cream caps and plastic bottle caps.

• Automatic positioning system: The system is mainly composed of sensors and positioning devices. Sensors are installed at each workstation of the turntable. When the plastic product arrives at the designated workstation, the sensor can accurately detect its position information and transmit the signal to the control system. The positioning device accurately adjusts the position of the plastic product based on the received signal to ensure that the position of each product during the thermal transfer process is accurate, thereby ensuring the accuracy of the transfer pattern.

• Thermal transfer system: It includes a heating component and a transfer head. The heating component generally uses an efficient heating element, such as a heating tube or a heating plate, which can quickly heat the transfer head to the set temperature. The material of the transfer head is usually a material with good thermal conductivity, such as silicone or a special alloy. The surface of the transfer head is customized according to the pattern to be transferred to ensure that the pattern can be clearly and completely transferred to the plastic product.

2. Working principle

• First, place plastic products such as cosmetic cream caps and plastic bottle caps on the feed station of the turntable. The turntable starts to rotate and transports the plastic products to each station in turn. When it reaches the thermal transfer station, the automatic positioning system accurately positions the plastic product. At the same time, the transfer head of the thermal transfer system has been heated to a suitable temperature by the heating component. The transfer head descends and fits tightly with the surface of the plastic product, and the pre-printed pattern on the transfer paper is transferred to the plastic product by hot pressing. After the transfer is completed, the transfer head rises, the turntable continues to rotate, and the transferred plastic product is transported to the discharge station to complete the entire thermal transfer process.

3. Scope of application

• It is mainly suitable for thermal transfer of various round plastic products, such as cosmetic cream caps, plastic bottle caps, plastic hoses, etc. These plastic products are widely used in cosmetics, pharmaceuticals, food and other industries. Through thermal transfer, brand logos, product information, decorative patterns, etc. can be added to its surface to enhance the beauty and recognition of the product and meet the market's demand for personalized product packaging.

4. Operation process

• Preparation: Install the transfer paper in the corresponding position of the thermal transfer system to ensure that the pattern on the transfer paper is correct. Turn on the machine, preheat the thermal transfer system, and set appropriate transfer temperature, pressure, turntable speed and other parameters according to the material of the plastic product and the requirements of the transfer pattern. Check whether the automatic positioning system is working properly.

• Feeding operation: Place plastic products such as cosmetic cream caps and plastic bottle caps neatly on the feed station of the turntable, and be careful not to block the feed channel.

• Thermal transfer process: Start the turntable and observe the operation of plastic products at each station. When arriving at the thermal transfer station, pay attention to check the positioning effect of the automatic positioning system and the quality of thermal transfer. If problems such as unclear transfer pattern and position offset are found, adjust the parameters in time.

• Discharging and inspection: After the transfer is completed, the plastic products are discharged from the discharging station, collected and sorted, and the transfer effect is inspected. If the next batch of plastic products needs to be thermally transferred, repeat the above steps.

|

Cylinder Flame treatment Machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

LC-F2 Cylinder flame treatment Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

Cylinder Flame treatment Machine//Advantage |

|

|

Function |

|

|

Main configuration |

|

|

Accessories included |

|

|

Cylinder flame treatment Machine//Technical support |

|

|

Printing elements |

To achieve the Machine capabilities, Please notice

|

Summary︰

Polyolefin material has excellent chemical resistance and good processing properties, which is why it is used as the main container manufacturing material. However, polyolefin materials are non-polar molecules with low surface tension and poor affinity for ink, so the printability is not good, and the ink is easy to fall off. For this reason, polarizing the surface of the polyolefin material becomes a pre-press treatment An important step, there are many methods for polarizing treatment at present: flame treatment, high frequency treatment, plasma treatment, and chemical oxidation treatment. Flame treatment is the most effective and simplest method for polarizing container polyolefin materials. When you buy a semi-automatic screen printing machine and find that the ink adhesion is not good, you may wish to consider the flame treatment procedure. Nowadays, many users buy fully automatic screen printing machines, which basically regard flame treatment as standard configuration, so you don't need to worry too much.