Model No.︰M-4000UVS2

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 3685 / pc

Minimum Order︰1 pc

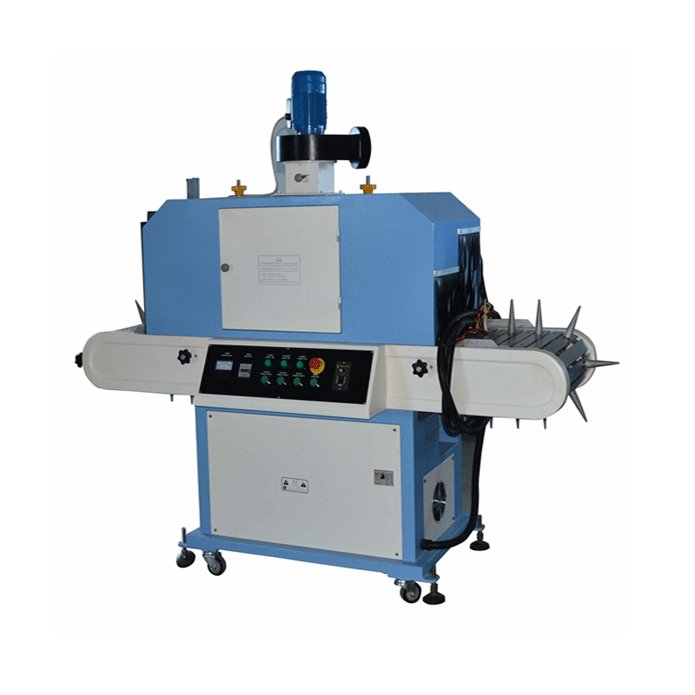

Conveyor belt type UV curing machine

● Structural features: It consists of a conveyor belt, UV lamp, reflector, cooling system, control system, etc. The conveyor belt is responsible for conveying round bottles, the UV lamp generates ultraviolet rays required for curing, the reflector can improve the utilization rate of ultraviolet rays, the cooling system prevents the equipment from overheating, and the control system is used to adjust parameters such as curing time and conveyor belt speed.

● Working principle: The round bottle is placed on the conveyor belt and enters the UV curing area as the conveyor belt moves. Under the irradiation of ultraviolet rays, the UV ink and coating on the surface of the round bottle are quickly cured.

● Applicable scenarios: It is suitable for large-scale production and can be combined with other production equipment such as screen printing machines and filling machines to form an assembly line operation to improve production efficiency. It can handle round bottles of various materials. By adjusting the conveyor belt speed and UV lamp power, it can adapt to the curing needs of round bottles of different diameters and heights.

|

M-4000UVS2 Cylinder UV Drying Machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

M-4000UVS2 Cylinder UV Drying Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

M-4000UVS2 Cylinder bottle UV Curing Machine//Advantage |

|

|

Function |

|

Summary︰ There is a certain difference between the UV curing process of circular products and the UV curing of flat products. Usually, circular products need to be printed with UV ink in the circumferential direction. Rotate while irradiating light to ensure UV curing effect. Curved surface UV curing machine is widely used in plastic packaging, cosmetics, washing products, pharmaceutical industry, glass packaging and other industries. Conical or frustum-shaped supports are installed on its conveyor belt, which can support the bottles and the speed can be adjusted. It is used in conjunction with semi-automatic curved screen printing machines, and is a very popular product for small and medium printing companies.