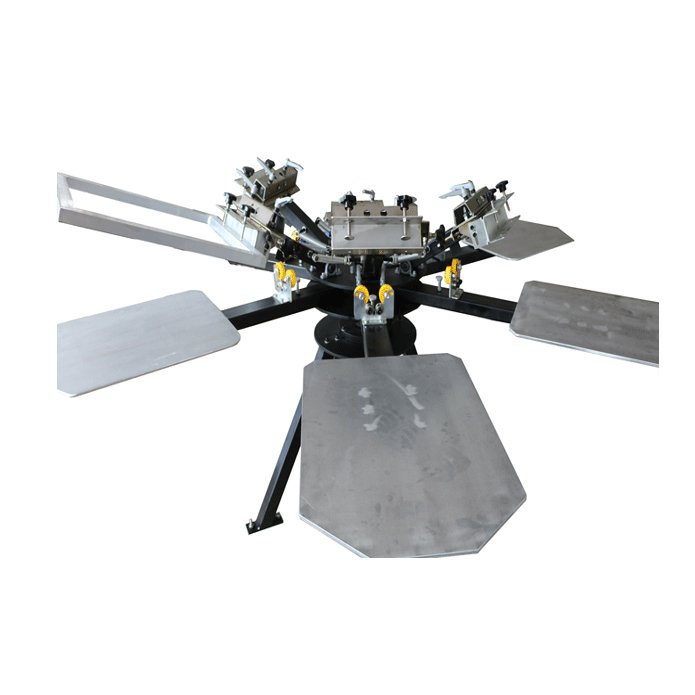

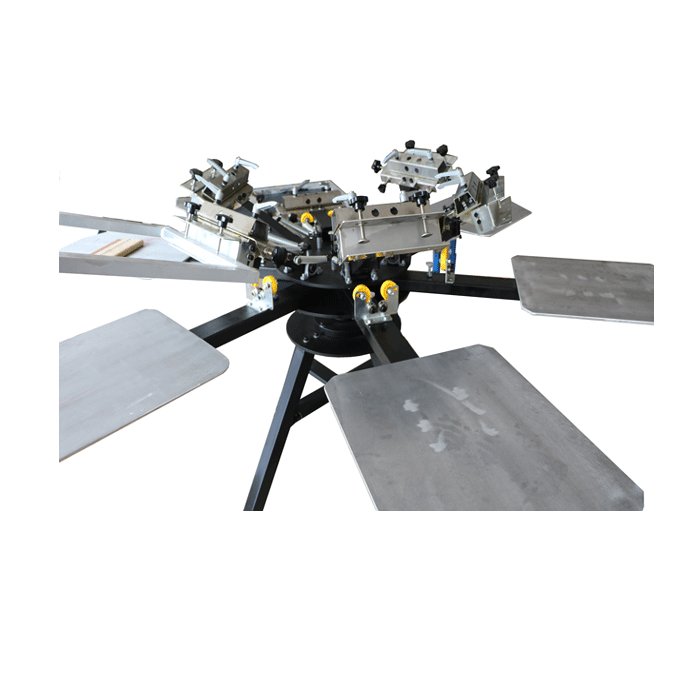

Model No.︰SM8-4050E

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 1800 / pc

Minimum Order︰1 pc

Principle

The Octopus manual screen printing machine squeezes the ink through the mesh of the screen plate to transfer to the substrate to form images and texts. Its ink pad and screen plate rotate in two layers, and the workstation rotates smoothly and automatically and accurately. Each workstation can be operated independently and the color registration is accurate.

Structure

• Ink pad: It is usually a special aluminum alloy high-temperature resistant printing table. The size can be customized according to customer requirements. It will not deform when overheated to ensure printing accuracy. It can also be equipped with a suction plate to complete the production of transfer paper.

• Screen plate: Generally, nylon screen is stretched on a metal or wooden rectangular frame. The pattern on the screen is partially hollowed out to allow the ink to pass through.

• Scraper: It is used to squeeze the ink so that the ink is transferred to the substrate through the mesh. The material, hardness and angle of the scraper will affect the printing effect.

• Transmission device: Both the screen and the worktable can rotate around the central axis, without electricity and air source, and no energy cost.

• Fine-tuning device: After the screen is fixed, the knob of the fine-tuning system can be used to make fine adjustments to the printing head in the front, back, left, right, up and down directions to achieve precise alignment and control of the screen tension.

• Bracket: Professional frame design, conical bracket ensures the stability of the machine and is sturdy and resistant to handling.

|

SM8-4050E Manual 8-color Garment screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

|

|

SM8-4050E Manual 8-color garment screen printing Machine //Parameters |

|

|

Technical parameters |

SM8-4050E 8-colour Manual rotating flat screen printing machine

|