Model No.︰HH-TC632

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 5840 / pc

Minimum Order︰1 pc

Principle

The hydraulic hot stamping machine mainly uses liquid pressure to transmit power based on Pascal's law. When it is working, the motor drives the oil pump to extract the hydraulic oil from the oil tank, and the hydraulic oil enters the hydraulic cylinder through the pressure control valve group. Under the pressure of the hydraulic oil, the piston in the hydraulic cylinder drives the hot stamping plate to move downward, so that the hot stamping paper and the hot stamping object fit closely. At this time, the heat and pressure on the hot stamping plate transfer the hot stamping materials such as anodized aluminum on the hot stamping paper to the surface of the hot stamping object, completing the hot stamping process. When the hot stamping is completed, the hydraulic oil flows back to the oil tank, and the hot stamping plate returns to the initial position under the action of the reset device.

Application structure

• Body frame: usually constructed of metal materials (such as steel), providing a stable support structure for the entire machine, ensuring that the machine will not shake or deform during the hot stamping process, affecting the hot stamping effect.

• Hydraulic system: including components such as oil pump, hydraulic cylinder, hydraulic oil, pressure control valve group and oil tank. The oil pump is the power source, which delivers hydraulic oil to the system; the hydraulic cylinder is the actuator, which drives the hot stamping plate to move; the hydraulic oil is the medium for transmitting power; the pressure control valve group is used to control the pressure and flow of the hydraulic oil; the oil tank is used to store the hydraulic oil.

• Heating device: Generally located inside the hot stamping plate, the hot stamping plate is heated by a heating element (such as a heating wire) to make the hot stamping plate reach the appropriate hot stamping temperature. The heating device needs to have precise temperature control function to meet the requirements of different hot stamping materials and hot stamping objects.

• Hot stamping plate and bottom mold: The hot stamping plate is usually made of metal with a flat and smooth surface. Its shape and size are determined according to the hot stamping requirements. The bottom mold is the component corresponding to the hot stamping plate, which is used to place the hot stamping object. Its surface shape matches the shape of the hot stamping object to ensure that the two fit closely during the hot stamping process.

• Control system: It consists of an electrical control cabinet, an operation panel, and sensors. The electrical control cabinet is equipped with control circuits and controllers. The operation panel is used to set the hot stamping parameters (such as temperature, pressure, time, etc.). The sensor is used to detect the position, temperature, pressure and other information of the hot stamping plate, and feed it back to the control system to achieve precise control of the hot stamping process.

|

Hydraulic embossing stamping Machine //Structure |

||

|

Working table |

High strength Steel plate , size: 480*600mm. |

|

|

Stamping Head drive |

Hydraulic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Max Pressure |

20T |

|

|

Hydraulic embossing stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

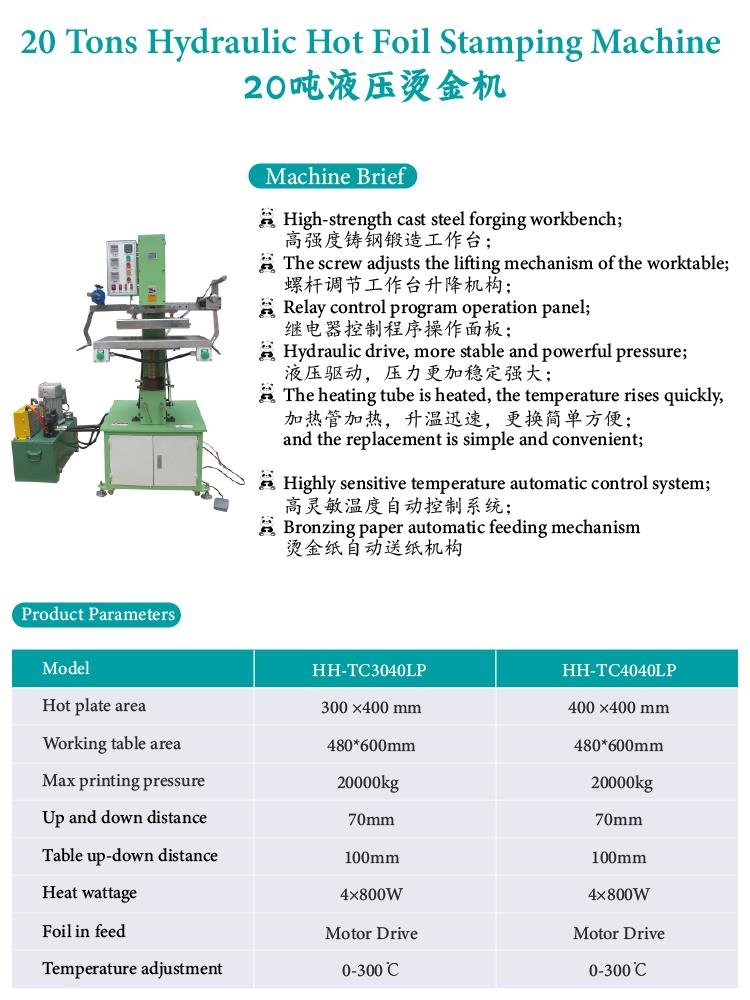

Hydraulic embossing stamping Machine //Parameter |

||

|

Technical parameters |

HH-TC631 |

HH-TC632 |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Hydraulic embossing stamping machine //Advantage |

||

|

Function |

|

|

Summary︰

Hydraulic hot stamping machine is a hot stamping machine that uses hydraulic oil as a power source. Due to the small compression ratio of the liquid, the pressure of the hot stamping machine is strong and stable. It can be used for hot stamping and embossing in paper packaging, gift boxes and wood products. has a wide range of applications. The hydraulic hot stamping machine is supplied with fluid by a hydraulic pump that stores hydraulic oil, and the direction of the fluid is controlled by a hydraulic valve to realize actions such as hot stamping and lifting. The pressure is between 10 tons and 120 tons. Typically, the larger the ironing size, the greater the pressure required.

Production Advantage ︰

1. Efficient: Compared with pneumatic devices, the hydraulic system can quickly and accurately complete the up and down movements of the ironing plate with high efficiency.

2. Sensitivity: The fluid in the hydraulic system is basically incompressible, and there is no hysteresis effect. Once pneumatically operated, the ironing plate can rise and fall quickly, with high sensitivity.

3. Reliable: Hydraulic components have a simple and durable structure and can withstand high pressure and high-speed operation. They also have self-lubricating and self-cooling properties, allowing them to work stably for a long time.

4. Adaptation: Adapt to various working environments and working conditions, such as high temperature, low temperature, high altitude, humidity, corrosion, etc.

5. Safety: Various safety protection devices and control systems can be used to ensure the safety of the ironing board.

The hydraulic hot stamping machine is guaranteed to achieve stable and continuous high pressure, and is suitable for hot stamping and concave and convex embossing of large-size products.