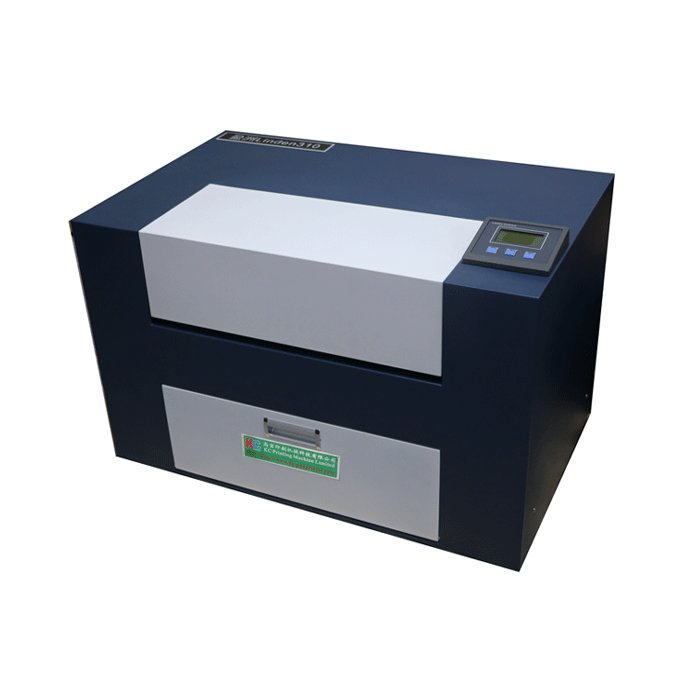

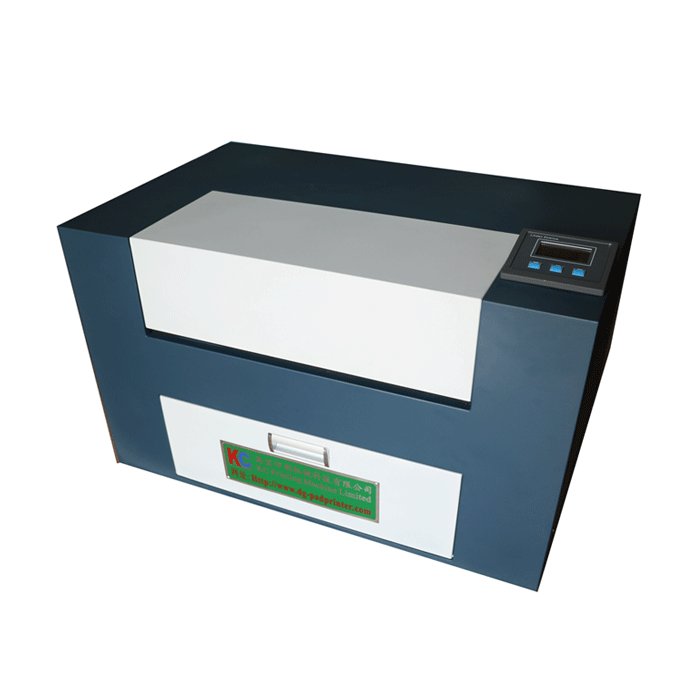

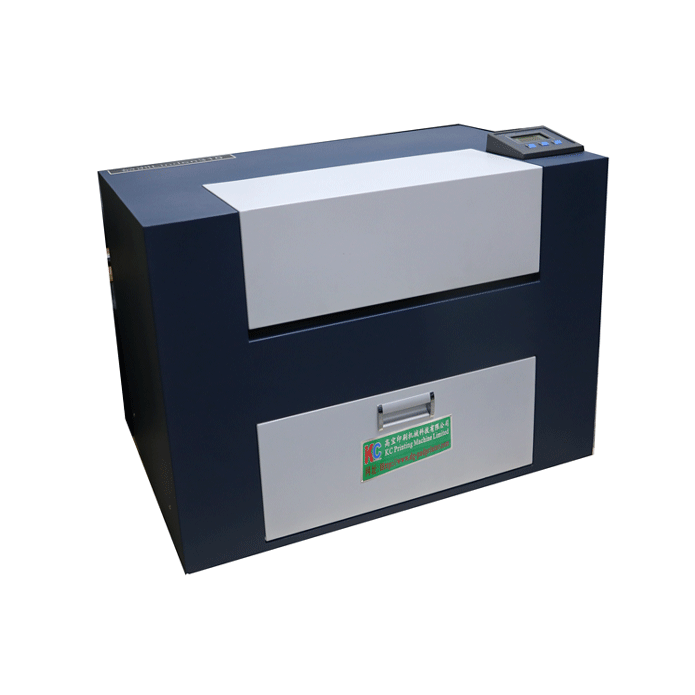

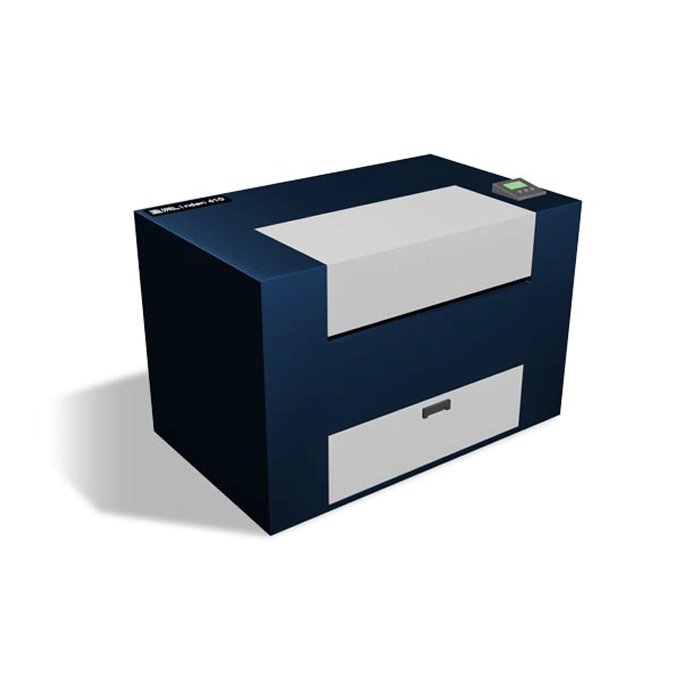

Model No.︰PM-410FL

Brand Name︰LC

Country of Origin︰-

Unit Price︰US $ 5840 / pc

Minimum Order︰1 pc

Working Principle

• A laser phototypesetter is a device that converts graphic information in a computer into optical signals and focuses the image on a photosensitive material (film) through an optical system. It is mainly composed of a laser light source, an acousto-optic modulator, a scanning system, and a photosensitive material conveying system. The computer sends the graphic information to the phototypesetter in the form of a digital signal. The laser beam generated by the laser light source passes through the acousto-optic modulator, and the intensity and on-off of the laser are changed according to the digital signal to form a modulated laser beam. The scanning system enables the laser beam to scan the photosensitive material (film) with high precision. The photosensitive material moves under the drive of the conveying system. After laser scanning and exposure, a latent image of the image is formed on the film. After subsequent development and other processing, the final film can be obtained.

Application Scenarios

• It is mainly used in small film output centers and plays a key role in the field of printing and platemaking. For example, film films for small printing factories to produce books, picture albums, leaflets and other printed materials can also be used to make some simple packaging design, label printing and other films.

Advantages

• Output width and resolution: The output width of 405mm can meet the needs of small film output centers to produce a variety of regular-sized printed films. The resolution of 3000DPI (dots per inch) can ensure the accuracy of the output film, make the details of the graphics clear, and can output high-quality images and fine text content to meet the clarity requirements of printing plate making.

• Ease of operation: The operation is simple and convenient, reducing the training cost and difficulty of operators. For small film output centers, it can be used by operators who do not need professional and long-term training, reducing labor costs.

• Low cost: The price of the equipment itself is relatively low compared to large and high-end phototypesetters, which is suitable for the capital budget of small enterprises. At the same time, during operation, due to its miniaturized design, the energy consumption is relatively low and the maintenance cost is not high, which has an advantage in overall cost.

|

Laser film imagine setter //Usage and characters |

|

|

Guide |

|

|

Application fields |

Film output during plate-making process of: pad printing, screen printing , Letterpress, Adhesive sticker printing, Bronzing, Middle-precision Grave printing, Middle-precision Offset Printing .Garment screen printing field. |

|

Laser film imagine setter //Parameter |

|

|

Technical parameters |

PM-410FL |

|

|

|

PM-510FL |

|

|

|

|

PM-610FL |

|

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Laser imagine setter //Advantage |

|

|

Function |

|

Summary︰

Traditional printing technology requires plate making, and plate making also mostly requires printing negatives to distinguish between printed and non-printed areas. The task of making plate negatives is mainly done by the film output machine. The manuscripts designed by design software such as Coreldraw or photoshop are rasterized by RIP, recorded on the film by the laser head of the film output machine to form graphic and non-graphic areas, and then developed and fixed to form the printing plate. Printing negatives is a key element in making high-quality printing plates.

In the field of special printing, such as pad printing, silk screen printing, hot stamping, etc., where precision is not required, the requirements for exposure film are: The format is not large, the quantity is not high, and the requirements are not strict, then the use of high-end laser imagesetters is a big deal. Therefore, film output machines specially designed and produced for these printing market segments came into being..