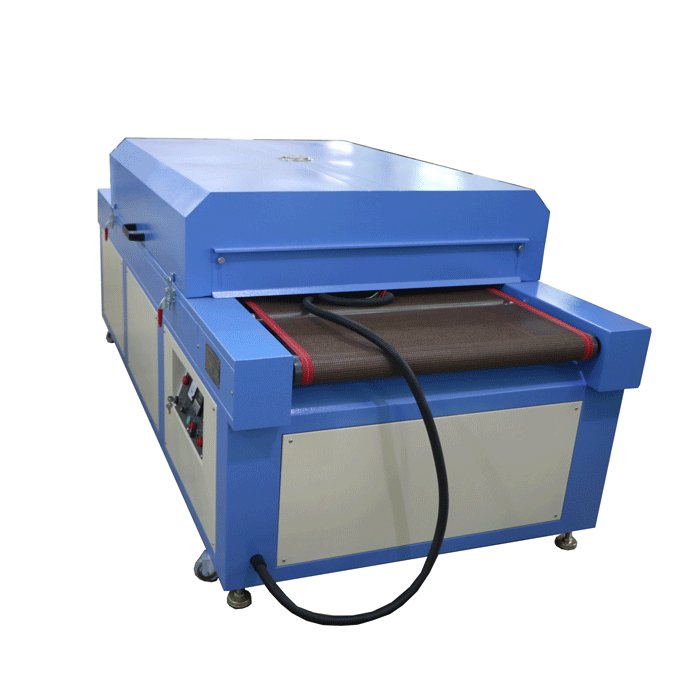

Model No.︰M-04XIR

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 6397 / pc

Minimum Order︰1 pc

Teflon conveyor belt

• Working principle: The motor drives the roller, which drives the Teflon conveyor belt to operate and realize the material conveying. Its adjustable speed is achieved by controlling the motor speed through the frequency converter, and the conveying speed can be flexibly adjusted according to different production needs.

• Application scenarios: Widely used in food processing, electronic and electrical production and other industries, such as conveying biscuits and other foods in food baking, and conveying small electronic components in the electronics industry.

• Advantages: Teflon material has good non-stickiness, which can prevent material adhesion; high chemical stability, resistant to corrosion by various chemical substances; high temperature resistance, can work stably in high temperature environment; high efficiency and low loss are mainly due to its smooth surface and low friction, which can effectively reduce energy loss during transportation, and has good wear resistance and long service life.

Button panel

• Working principle: The button panel is mainly connected through circuits. When the button is pressed, it will change the on-off state of the circuit, thereby sending a signal to the control system of the equipment. For example, the conduction of the circuit and the transmission of the signal are realized by conductive rubber or micro switches.

• Application scenarios: Almost all electronic devices have applications, such as industrial control equipment, household appliances (such as microwave ovens, washing machines), electronic testing instruments, etc.

• Advantages: It is convenient for users to operate and control, and can intuitively select and set the device functions; through reasonable layout and design, multiple function buttons can be integrated to save equipment space.

Imported height-adjustable IR drying oven with far-infrared heating

• Working principle: Far-infrared heating uses far-infrared rays emitted by far-infrared radiators. After being absorbed by the heated object, its molecules and atoms resonate, causing vibration and rotation of molecules and atoms, resulting in an increase in the temperature of the object, thereby achieving drying. Height adjustment is to change the distance between the drying oven and the object to be dried through mechanical structures (such as screws, slide rails, etc.) to adapt to items of different sizes and drying requirements.

• Application scenarios: Used for drying paints and coatings in the coating industry; drying inks in the printing industry; drying agricultural products in the food industry, etc.

• Advantages: Fast heating speed, able to heat the surface and interior of the object at the same time in a short time; high thermal efficiency, significant energy saving effect; precise control of drying intensity by adjusting the height to ensure uniform drying quality, and imported equipment is usually more reliable in quality and performance.

|

IR Drying Machine//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

IR Drying tunnel //Parameter |

||

|

Technical parameters |

M-03XIR |

M-04XIR |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

IR Drying tunnel //Advantage |

||

|

Function |

heated with far-infrared ceramic heating rod and hot wind circuit make printed object dry evenly in the shortest time. Thus save power;

telflon coated conveyor belt can work properly and durable in high temperature.

The conveyor is driven by stepless change speed motor. Therefore, running speed of conveyor can be set arbitrary, Thus, The dryer can dry different thickness object.

openable covers on both side of heating room. Ceramic heating rod can be easily replaced by simply opening the cover of heating room.

Heating temperature can be set to any temperature between roon temperature to 300 degree. Tolerance of temperature is in +/-5 degree. |

|

Summary︰

Ink drying is an important indicator to measure the printing quality. The more common ways of ink drying are heat drying and UV drying. Heat drying is the drying method of solvent-based ink. In order to maintain the continuous delivery of products, the most common way to dry solvent-based ink is to use a tunnel furnace for processing. The tunnel drying furnace consists of a conveyor belt that can circulate and a device that can generate infrared rays. Composition, the product will be placed on the conveyor belt, driven by the motor, the conveyor belt will be transported to the infrared lamp at a constant speed to receive irradiation, and the solvent in the ink will be evaporated and sent to the outside.

Tunnel dryer can be connected with pad printing machine, screen printing machine, widely used in various types of plastic, glass, and clothing printing industries.