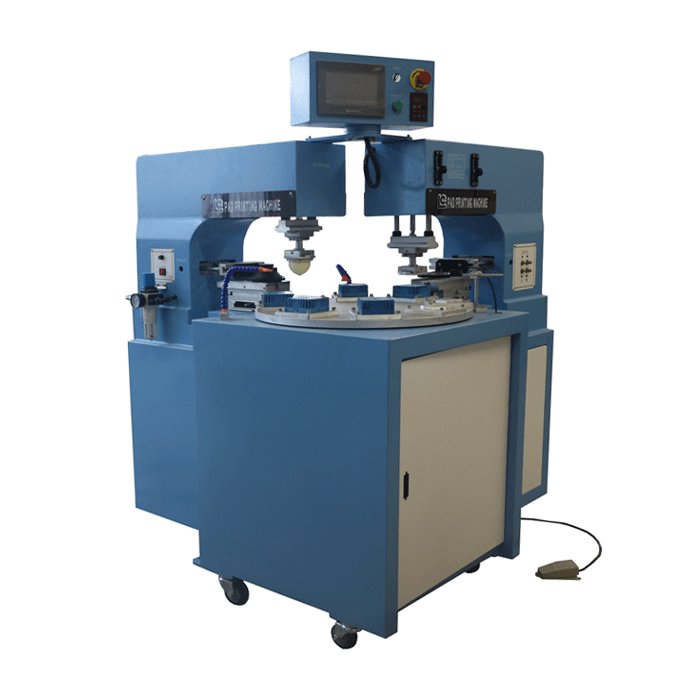

Model No.︰RPM208S

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 12500 / pc

Minimum Order︰1 pc

Main structure

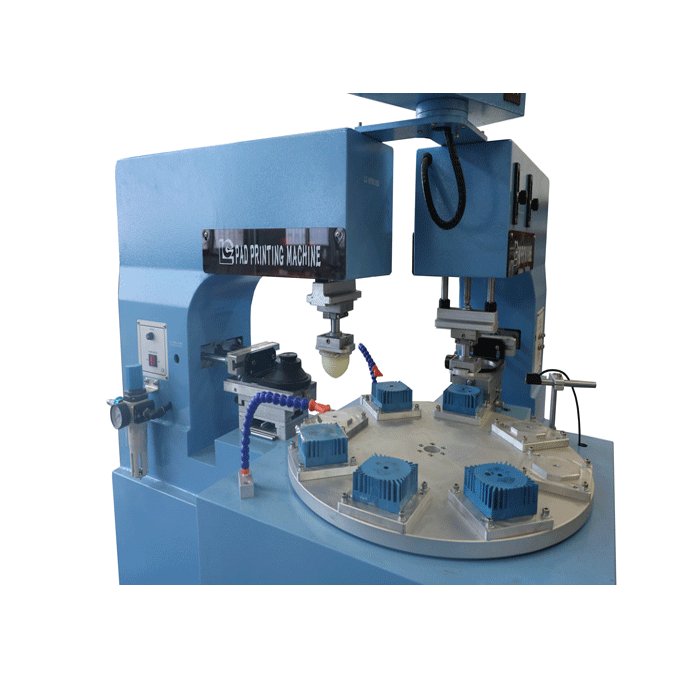

• Turntable device: It is one of the core components, used to place and fix the electric fan housing. Through the rotation of the turntable, the housing can be transported to different printing stations in turn to achieve multi-color printing.

• Printing system: including printing rubber head, steel plate, oil cup, etc. The printing rubber head is responsible for transferring the ink on the steel plate to the electric fan housing; the steel plate is etched with patterns or texts to be printed; the oil cup is used to store and scrape off the excess ink on the steel plate.

• Loading and unloading device: The loading device can automatically transport the electric fan housing to be printed to the designated position of the turntable, and the unloading device automatically takes out the finished product after printing. The whole process does not require manual intervention, which improves production efficiency.

• Touch screen control system: Through the touch screen, the operator can intuitively set and adjust printing parameters, such as printing speed, rubber head stroke, ink supply, etc., and can also monitor the operating status of the equipment in real time, display fault information, and facilitate repair and maintenance.

Working Principle

When working, the feeding device places the electric fan casing to the initial position of the turntable, and the turntable rotates to send the casing to the first printing station. The printing rubber head descends, contacts the steel plate and is stained with ink, then rises and moves above the casing, and descends again to transfer the ink to the casing to complete the first printing. Then the turntable continues to rotate, the casing arrives at the second printing station, and the above steps are repeated for the second printing, thereby realizing two-color printing. After printing is completed, the unloading device removes the finished product.

Advantages

• Improve production efficiency: The automated loading, printing and unloading processes, as well as the rapid rotation and positioning of the turntable, greatly shorten the printing time of a single product, improve the overall production efficiency, and are suitable for large-scale production.

• High printing quality: The touch screen accurately controls the printing parameters, ensures the accuracy and consistency of the printing, makes the pattern and text clear, bright and firm, and improves the appearance quality and grade of the product.

• Easy operation: The touch screen interface is simple and intuitive, and the operator can easily master the operation method of the equipment without complex training, reducing the labor intensity and the skill requirements for the operator.

• Wide range of applications: The turntable, rubber head, steel plate and other components can be adjusted according to different electric fan casing shapes, sizes and printing requirements. It can also be used for printing other plastic products of similar shapes, which improves the versatility and flexibility of the equipment.

|

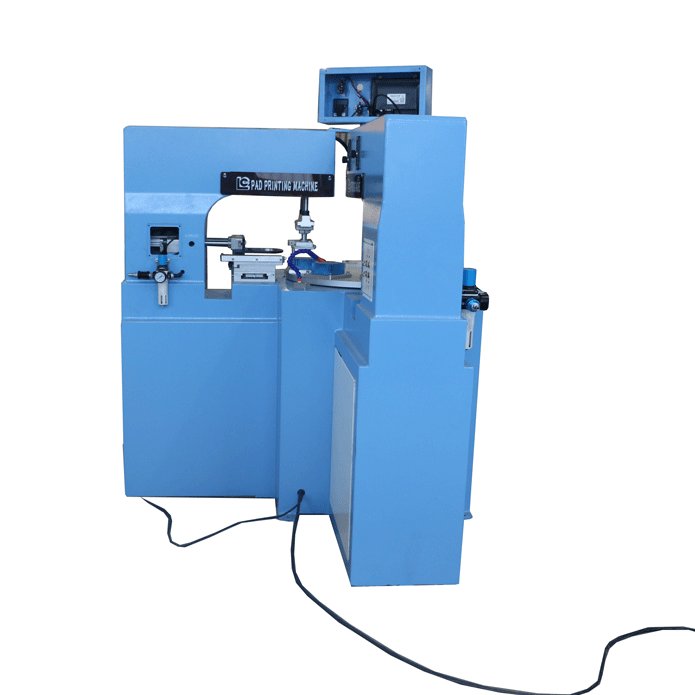

Two colors pad printer with 6-station rotating workbench //Structure |

|

|

Working table |

6-station rotating workbench |

|

Ink supply system |

90mm diameter Closed cup type system |

|

Plate type and size |

steel sheets plate. |

|

Pad dropping control |

Simple-cylinder , Continue pressing, servo motor |

|

Ink drying |

Heat air |

|

Two colors pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

Two colors pad printer with 6-station rotating plate //Parameter |

|

|

Technical parameters |

RPM280S Two colours sealed cup pad printer with 6-station rotating workbench

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors pad printer with 6 stations workbench //Advantage |

|

|

Function |

|