Model No.︰S-125S

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 2573 / pc

Minimum Order︰1 pc

Flat and round multi-purpose screen printer:

1. Main features

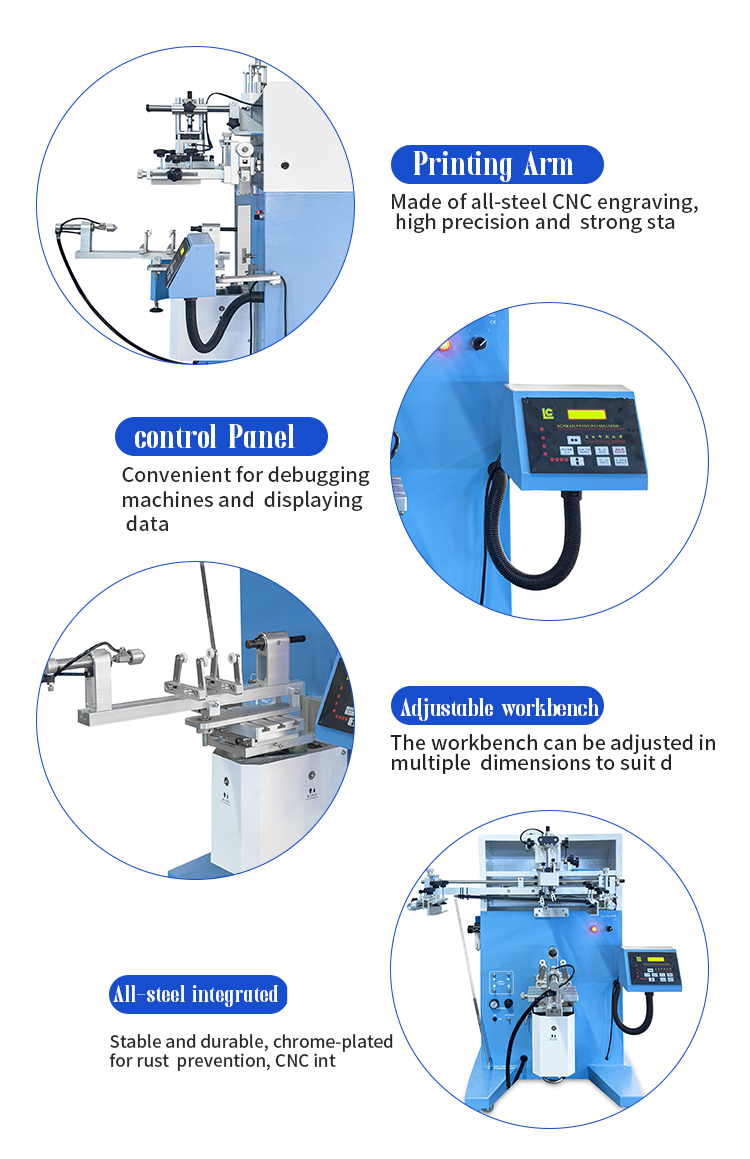

Microcomputer control

• Precise control parameters: Through the microcomputer control system, key parameters such as printing speed, scraper stroke, and the distance between the screen and the substrate can be accurately set and adjusted. For example, when printing fine electronic product logos, the scraper speed can be slowed down to ensure uniform ink transfer and make the pattern clear and accurate.

• Memory function and automatic operation: With memory function, it can store a variety of different printing parameter settings, which is convenient for direct call when repeatedly printing the same or similar products. At the same time, it can realize automated operation processes, such as automatic scraping and automatic ink return, to improve printing efficiency.

Flat and round dual-purpose

• Applicable to various shapes of substrates: It can print flat materials such as paper, plastic sheets, metal sheets, etc., and can also print round objects, such as glass bottles, plastic bottles, cylindrical electronic product shells, etc. For some companies with multiple packaging forms or product shapes, this feature makes it unnecessary to purchase multiple different types of screen printers.

• Flexible switching mode: It is easy to switch between flat printing mode and round printing mode. Generally, it can be achieved by simply adjusting the fixture, positioning device or screen angle, and the conversion process is fast and does not take up too much time.

Workbench lifting

• Easy to operate and adjust: The workbench can be raised and lowered freely, which is convenient for operators to adjust the optimal printing distance between the screen and the substrate according to the thickness and size of the substrate. For example, the workbench can be raised when printing thicker wood boards, and the workbench can be lowered when printing thin paper to ensure uniform printing pressure and improve printing quality.

• Adapt to the integration needs of different equipment: When forming a production line with other production equipment, the workbench lifting function helps to better connect the screen printer with upstream and downstream equipment to achieve automated continuous production.

High cost performance

• Price advantage: Considering its functions and performance, the price is relatively reasonable. Compared with some single-function or high-end but expensive screen printers, it can meet a variety of printing needs while having a more controllable cost, which is an economical choice for small and medium-sized enterprises or startups.

• High cost-effectiveness: On the basis of ensuring printing quality and efficiency, it can be applied to the printing of a variety of products and shapes, reducing the investment of enterprises in purchasing multiple equipment due to product diversification, and reducing equipment procurement costs. At the same time, its stable performance and low maintenance rate also reduce the subsequent maintenance costs.

2. Application Scope

• Advertising and packaging industry: It can be used to print various flat advertising materials, such as posters, leaflets, product packaging boxes, etc.; it can also print patterns and texts on round packaging bottles and cans, such as cosmetic bottles, beverage bottles, etc.

• Electronics industry: Print logos on the shells and circuit boards of electronic products, whether it is a flat mobile phone back cover, tablet computer shell, or cylindrical electronic equipment parts, high-quality printing can be achieved.

• Crafts and gifts industry: It can be used for decorative printing on various crafts and gifts, including flat wooden crafts, metal ornaments, and round glass crafts, ceramic vases, etc., to increase the artistic value and ornamentality of the products.

|

S-125S Multi-function cylinder screen printing machine//Structure |

|||

|

Working table |

Cylinder workbench/The elliptical cylinder workbench/Flat workbench |

||

|

Actions |

Up-down of working table |

||

|

To be printed |

|

||

|

Squeegee stroke |

Adjust the Limited switch |

||

|

Squeegee and screen plate control |

High precision guide shaft |

||

|

S-125S Multi-function screen printing machine//Usage and characters |

|||

|

Guide |

|

||

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

||

|

S-125S Multi-function screen printing Machine //Parameters |

|||

|

Technical parameters |

|

||

|

Works supply |

|

||

|

Ship parameters |

|

||

|

|||

|

H.S.CODE |

8443198000 |

||

|

Certificate |

CE |

||

|

S-125S Multi-function screen printing Machine//Advantage |

|||

|

Function |

|

||

| Fittings | Description | size | Price |

| 1 | IC Plate | 225usd | |

| 2 | 1416 bumper | 41usd | |

| 3 | Spring | 8usd | |

| 4 | Footswitch | 19usd. | |

Summary︰

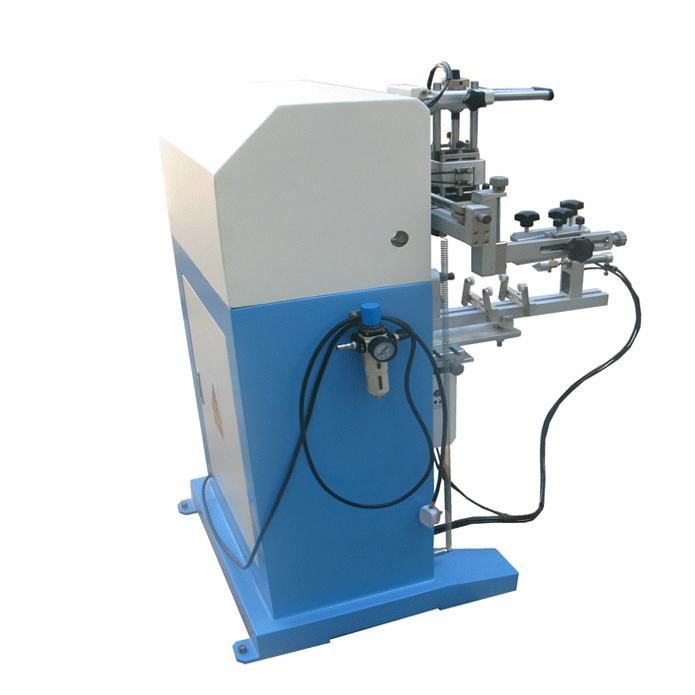

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.