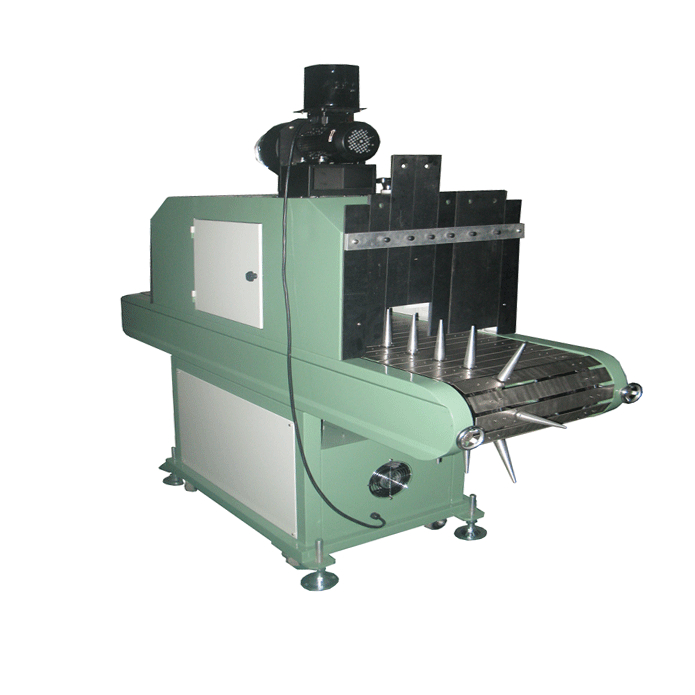

Model No.︰M-3000UVS2

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 3353 / pc

Minimum Order︰1 pc

UV dryer for round and oval products:

Working principle

Place the cups, bottles, tubes or other round and oval products that have been coated, screen-printed with UV ink, paint, etc. and need to be dried and cured on the corresponding conveying device or carrying station of the UV dryer. After starting the equipment, the UV lamp in the UV dryer will emit ultraviolet rays of a specific wavelength, which will be irradiated on the UV material on the surface of the product, so that the photoinitiator in it will be stimulated by ultraviolet rays to produce a chemical reaction, prompting the ink, paint, etc. to quickly change from liquid to solid, and achieve rapid drying and curing, and then the dried product can be taken out.

Main structure and features

• UV lamp and reflector:

• UV lamp: It is the core component for generating ultraviolet rays. Its power, wavelength and other parameters can be selected and configured according to different UV materials and product drying requirements. For example, for some thick-coated inks, a lamp with higher power may be selected to ensure a deep curing effect.

• Reflector: Surrounding the UV lamp, it is usually made of high-reflectivity materials. It can reflect and focus the ultraviolet light emitted by the lamp, improve the utilization rate of ultraviolet light, allow the product surface to be more fully irradiated, and enhance the drying and curing effect.

• Conveying or carrying device:

• Conveyor belt type: It is more suitable for batch-produced products such as cups and bottles. It can convey the products through the UV irradiation area in sequence at a stable speed to ensure that each product can receive uniform and sufficient ultraviolet irradiation for a long time, achieve efficient drying and curing, and can be connected with other production equipment to form a continuous production line.

• Turntable or clamp type: For tubes, irregularly shaped round or elliptical products, the turntable rotates or a specific clamp fixes the product so that it receives all-round ultraviolet irradiation in a fixed position, ensuring that the curved surface and parts at different angles of the product can be effectively dried and improve the curing quality.

• Control system:

• Parameter adjustment: It can accurately control the opening and closing time of the UV lamp, adjust the power of the lamp, and set key parameters such as the length of time the product stays in the drying area and the conveying speed, so as to flexibly adjust the drying process according to the characteristics of different products and different UV materials, and ensure the consistency and stability of the drying effect.

• Safety protection and monitoring: It has functions such as over-temperature protection and lamp abnormality alarm, and monitors the operating status of the equipment in real time to ensure that the equipment works under safe and reliable conditions, and facilitates operators to find and handle faults in time.

Advantages

• Fast drying speed: UV materials are cured instantly by ultraviolet irradiation, which greatly shortens the drying time and improves production efficiency compared with traditional natural drying or hot drying methods. It is especially suitable for large-scale and high-efficiency production scenarios.

• Good curing effect: It can make inks, coatings, etc. firmly adhere to the surface of products such as cups and bottles, forming a wear-resistant, scratch-resistant, and glossy curing layer, improving the appearance quality and service life of the product, and ensuring that the printed content such as patterns and texts are long-lasting and clear.

• Wide range of applications: Whether it is glass bottles, ceramic cups, or plastic tubes and other round and oval products of different materials, as long as they are coated with UV materials, they can be effectively dried and cured by adjusting the equipment parameters to meet the diverse production needs of products.

• Environmental protection and energy saving: Compared with some thermal drying equipment, UV dryers do not need to consume a lot of heat energy, the energy consumption is relatively low, and there will be no environmental pollution problems such as volatilization of organic solvents, which meets the requirements of environmentally friendly production.

|

M-3000UVS Cylinder UV Drying Machine//Usage and characters |

|

|

Guide |

|

|

Application fields |

|

|

M-3000UVS Cylinder UV Drying Machine//Parameter |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certificate |

CE |

|

M-3000UVS Cylinder bottle UV Curing Machine//Advantage |

|

|

Function |

|

|

Main configuration |

|

|

Accessories included |

|

|

M-3000UVS Flat UV Curing Machine//Technical support |

|

|

Printing elements |

To achieve the UV Drying Machine capabilities, Please notice

|

Summary︰ There is a certain difference between the UV curing process of circular products and the UV curing of flat products. Usually, circular products need to be printed with UV ink in the circumferential direction. Rotate while irradiating light to ensure UV curing effect. Curved surface UV curing machine is widely used in plastic packaging, cosmetics, washing products, pharmaceutical industry, glass packaging and other industries. Conical or frustum-shaped supports are installed on its conveyor belt, which can support the bottles and the speed can be adjusted. It is used in conjunction with semi-automatic curved screen printing machines, and is a very popular product for small and medium printing companies.