Model No.︰HM-TC181

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 600 / pc

Minimum Order︰1 pc

Manual hot stamping machine refers to the hot stamping machine that manually operates the hot stamping head up and down to perform the hot stamping action. Due to its low price, the market demand is also very strong. It can complete the processing of products with small orders, and can also make samples for customer products. The test can be seen in stores that sell hot stamping paper, hot stamping version or advertising processing. Except for the manual hot stamping action, the manual hot stamping machine is automatic, and its power consumption has not been significantly reduced, but it does not need compressed air, so it is more convenient to operate.

|

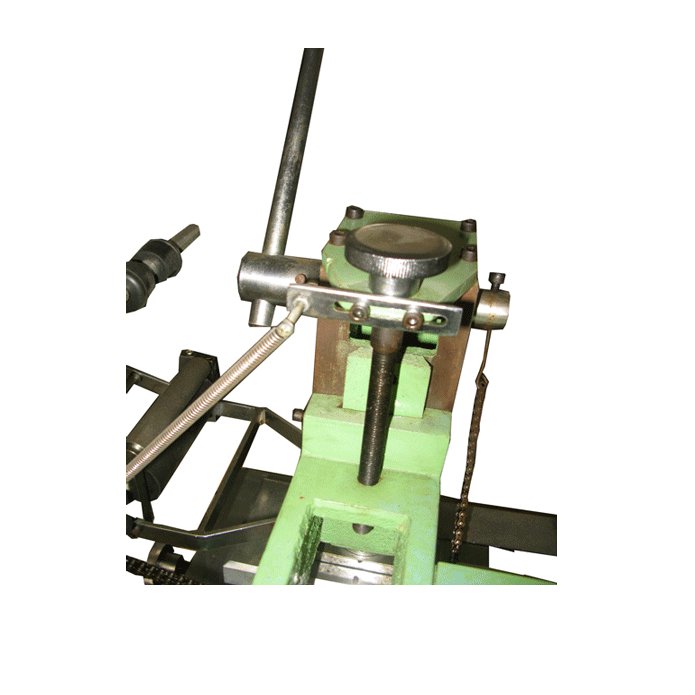

Manual hot stamping Machine //Structure |

||

|

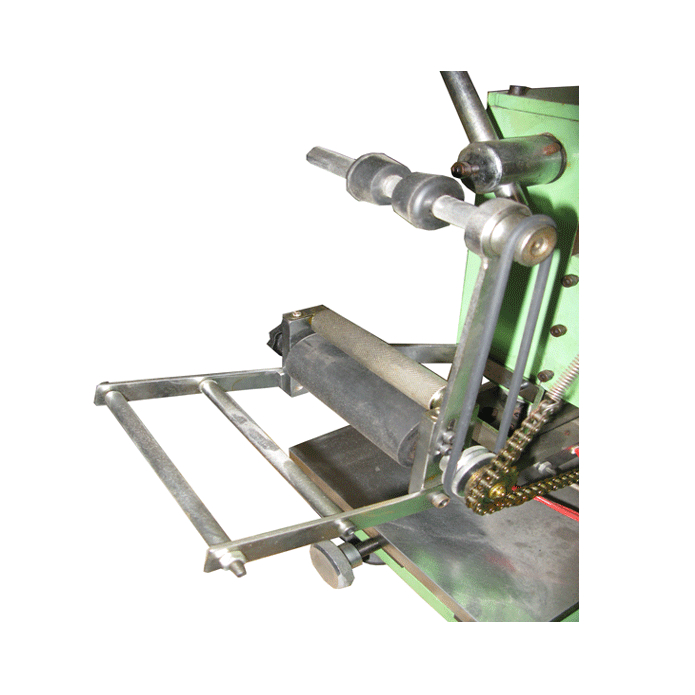

Working table |

Manual in-out , size: 250*280mm. |

|

|

Stamping Head drive |

Manual , Level keeping pressure |

|

|

Foil collecting method |

Chain -drive , Collecting time adjustable |

|

|

Press |

Vertical press |

|

|

Temperature control |

Heater tube, automatically controlling |

|

|

Foil collecting |

Automatically collecting |

|

|

Press adjustment way |

Up-down of Stamping plate |

|

|

Manual hot stamping machine//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Manual hot stamping Machine//Parameter |

||

|

Technical parameters |

HM-TC181 |

HM-TC182 |

|

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Manual hot stamping machine //Advantage |

||

|

Function |

|

|

Summary︰

Manual hot stamping machine refers to the hot stamping machine that manually operates the hot stamping head up and down to perform the hot stamping action. Due to its low price, the market demand is also very strong. It can complete the processing of products with small orders, and can also make samples for customer products. The test can be seen in stores that sell hot stamping paper, hot stamping version or advertising processing. Except for the manual hot stamping action, the manual hot stamping machine is automatic, and its power consumption has not been significantly reduced, but it does not need compressed air, so it is more convenient to operate.