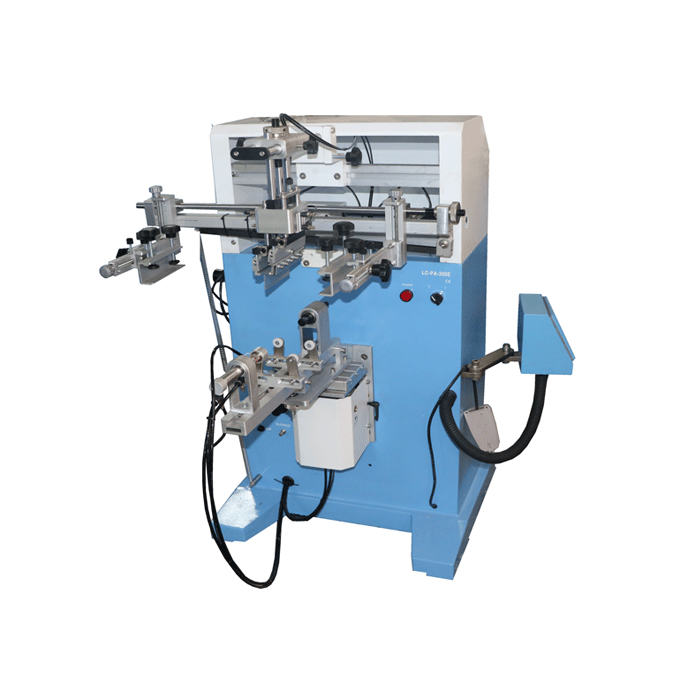

Model No.︰S-300E

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 1544 / pc

Minimum Order︰1 pc

Working principle

• Printing action control: This semi-automatic screen printer drives the up and down movement of the workbench through a pneumatic control system. When the screen printing program is started, the pneumatic device pushes the workbench up or down. For cups, bottles or cosmetic bottle caps with round, elliptical or flat surfaces, place them on the workbench and fix them in place.

• Printing process: Set the parameters of screen printing, such as the speed of the scraper, printing pressure, ink volume, etc., through the microcomputer operation panel. During printing, the screen plate (with the pattern to be printed on it) is located above the workpiece. When the workbench rises and the workpiece contacts the screen plate, the scraper moves on the screen plate and squeezes the ink through the mesh of the screen plate to the surface of the workpiece (cup, bottle, bottle cap), thereby completing the screen printing. Since objects of different shapes such as round, elliptical and flat surfaces can be printed, for curved objects, some special fixtures or mechanisms may be used during the printing process to ensure that the screen plate fits well with the surface of the object and that the ink is evenly distributed.

• Operation part: The microcomputer operation panel is the control center of the entire screen printer. Operators can input and adjust various screen printing parameters on the panel, select different printing modes (such as different modes for round, elliptical and flat surfaces), and monitor the working status of the screen printer, such as the current workflow stage, whether there is a fault and other information.

Application scenarios

• Packaging industry: used for printing various bottles and bottle caps, such as beverage bottles, cosmetic bottles and their caps. The brand name, pattern, ingredient description and other content of the product can be printed to improve the recognition and aesthetics of the product.

• Gift industry: screen printing on gifts such as cups, such as printing personalized patterns and blessings on commemorative cups and gift cups to increase the value of the gifts.

Advantages

• Applicable to various shapes: It can screen print on round, elliptical and flat objects, and adapt to cups, bottles, bottle caps and other shapes of different shapes. It has strong versatility and can meet the printing needs of various products.

• Accurate and flexible operation: The microcomputer operation panel makes the parameter setting accurate, and the operator can flexibly adjust according to different products and printing requirements to ensure printing quality. The pneumatically controlled workbench moves up and down more stably, which is conducive to ensuring the contact accuracy between the workpiece and the screen during the printing process and improving the printing effect.

• Semi-automatic advantages: Compared with fully automatic screen printing machines, semi-automatic screen printing machines have lower costs and higher efficiency than manual screen printing machines, which are suitable for small and medium-sized production enterprises.

For the printing of cylinders, elliptical cylinders, cones, especially hollow plastic containers, the most preferred choice is the curved surface screen printing machine. The curved surface screen printing machine transfers the left and right movement of the flat screen to the curved surface product through gear transmission or friction transmission. For the printing machinery on the linear contact surface, the continuous rotation of the product, and the part in contact with the surface will continuously receive the ink transfer on the screen to achieve printing.

The significant difference between the curved surface screen printing machine and the flat screen printing machine is that its fixture actually completes the rotation of the product, and the rotation process is in linear contact with the movement of the screen, and no slippage can occur. Therefore, the main elements of the curved screen printing machine are: screen printing screen, screen printing ink, screen printing squeegee, and the squeegee on the curved screen printing machine is usually a squeegee with a triangular cross-section. The screen printing jig has various forms, and its main feature is to ensure the precise and stable rotation of the product.

The curved screen printing machine can print tiny cylinders such as straws and pen refills with a diameter of 1mm, and can also print plastic barrels, oil barrels, and water heater shells with a diameter of more than 500mm. Screens and fixtures will do.

|

S-300E Multi-function screen printing machine//Usage and characters |

|

|

Guide |

|

|

Application |

Plastics soft tubes, Bottles, containers, Bucket, Cosmetic case, any Cylinder-object, Oval-object. |

|

S-300E Multi-function screen printing Machine //Parameters |

|

|

Technical parameters |

|

|

Works supply |

|

|

Package parameters |

|

|

H.S.CODE |

8443198000 |

|

Certificate |

CE |

Machine advantage

Summary︰

The most popular printing method for round and oval products is screen printing, and semi-automatic screen printing machines are the best-selling screen printing machines. Every year, more than 1,000 semi-automatic curved screen printing machines are sold from China to the world. Although in recent years, sales have increased The squeeze of the automatic screen printing machine continues to decrease, but it is still the model favored by small and medium enterprises worldwide.

The semi-automatic curved screen printer can print almost all cylinders and ellipsoids, involving almost all materials, and the diameter of the largest printed product can reach 1M. When it is used with flame treatment and UV curing machine, it is another contribution to environmental protection. The semi-automatic screen printing machine can only print one color at a time, and overprinting up to 10 colors can be achieved through positioning. It is also particularly suitable for printing on containers that are not suitable for automatic screen printing machines such as milk bottles and special-shaped bottles.