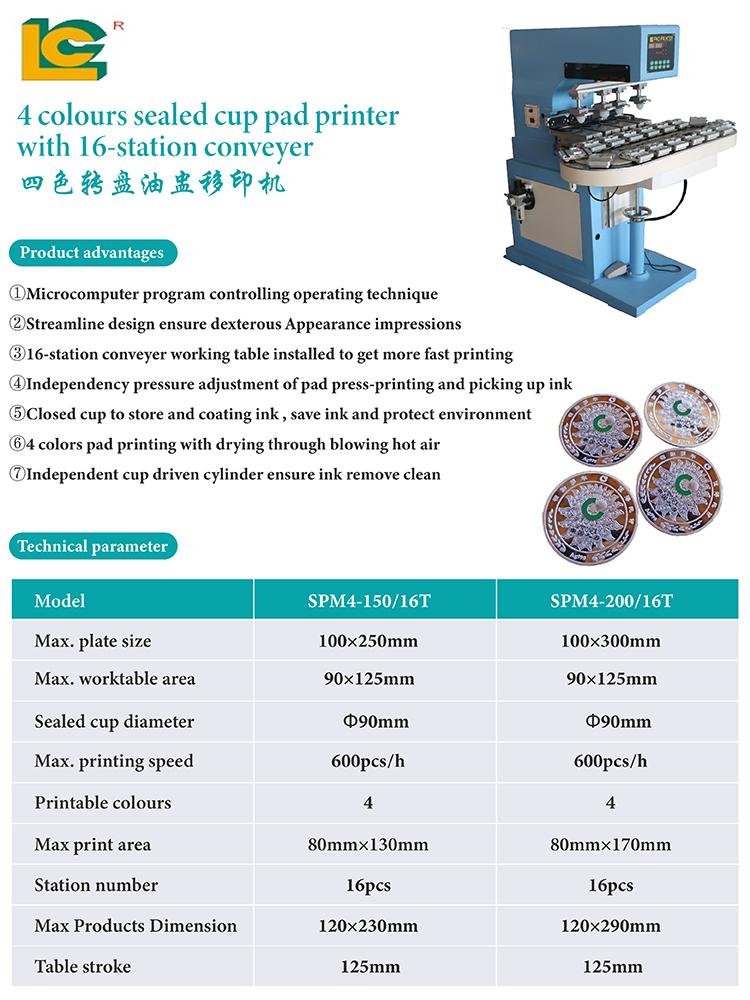

Model No.︰SPM4-150/16T

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 4500 / pc

Minimum Order︰1 pc

1. Turntable structure

• 16-station turntable: This is one of the core components of the pad printing machine. The turntable is divided into 16 working positions, which can handle multiple workpieces at the same time or complete different steps of pad printing at different positions. For example, some of the positions can be used to place the workpieces to be printed, some for printing, and some for subsequent processing such as drying. The turntable is controlled to rotate by a pneumatic drive device to ensure that each position can accurately stop at the designated operating position. Its high rotation accuracy is conducive to improving the efficiency and quality of pad printing.

2. Control system

• Microcomputer panel: As the control center of the pad printing machine, the microcomputer panel provides an intuitive and convenient operation interface. The operator can set various parameters through the panel, such as the rotation speed of the turntable, the dwell time of each position, the number of printings, etc. At the same time, the microcomputer can also monitor the working status of the pad printing machine. When a fault or abnormal situation occurs, it can display error information in time to facilitate maintenance and adjustment.

3. Power system

• Pneumatic control: Compressed air is used as a power source to drive the various actions of the pad printing machine. Pneumatic control has the advantages of fast response speed and precise movement. For example, the up and down movement of the printing head can be accurately controlled by the pneumatic device, so that the pattern can be transferred to the workpiece under appropriate pressure. Moreover, the pneumatic system is relatively simple, with low maintenance cost and high reliability.

4. Ink supply system

• Ink supply method of oil cup: The oil cup is a closed ink supply device. During the pad printing process, the ink is placed in the oil cup, and the printing head obtains the ink by rolling or dipping on the surface of the oil cup. The advantage of this method is that the ink is not easy to volatilize, which can maintain the stability of the ink performance and reduce the waste of ink. At the same time, the oil cup can accurately control the supply of ink according to the printing needs, so as to ensure the clarity and color consistency of the printed pattern.

|

4 colors pad printer with 16-station conveyer//Structure |

|

|

Working table |

16-station conveyer-type working table |

|

Shuttle stroke |

125mm |

|

Ink supply system |

90mm diameter Closed cup type system |

|

Plate type and size |

0.3mm Thin steel sheets plate. |

|

Pad dropping control |

Simple-cylinder , Continue pressing |

|

Ink drying |

Heat air |

|

4 colors pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

4 colors pad printer with 16-station conveyer//Parameter |

|

|

Technical parameters |

SPM4-150/16T 4 colours sealed cup pad printer with 16-station conveyer

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

4 colors pad printer with conveyer //Advantage |

|

|

Function |

|

Summary︰

In European countries, users tend to buy pad printers with closed ink cups. This type of pad printer is equipped with a structure similar to a closed oil cup to store ink to reduce VOC volatilization during printing. In the pad printing industry, UV pad printing inks and water-based inks are used very little, and solvent-based inks are mainly used. The solvent contained in the ink volatilizes into the air and will cause certain damage to the operator’s respiratory system. Ink is an effective way to reduce this damage. Since the ink is enclosed in a relatively closed space, its viscosity and printability will also maintain a certain degree of stability, which is beneficial to pad printing quality.