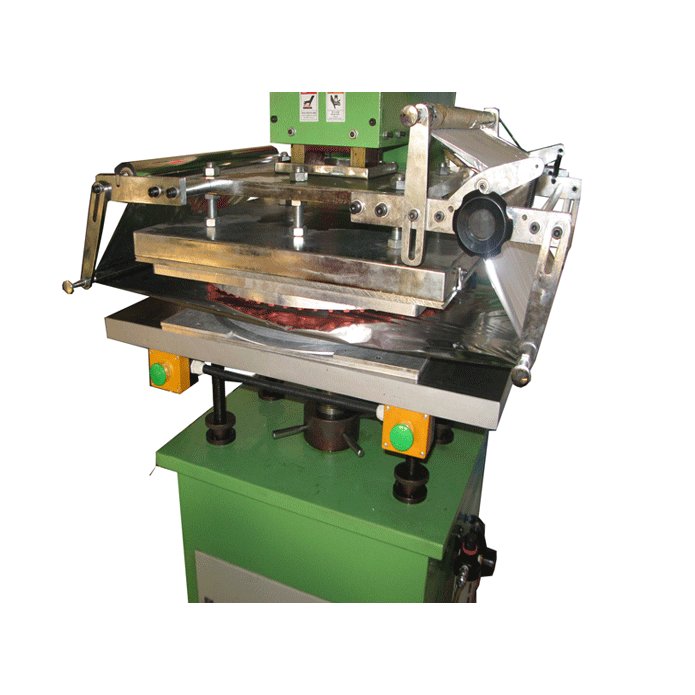

Model No.︰H-TC233

Brand Name︰LC

Country of Origin︰China

Unit Price︰US $ 8900 / pc

Minimum Order︰1 pc

1. Wide range of applicable materials

• This hot stamping machine can be used for hot stamping of materials such as paper, film, wood board and leather. For hot stamping of paper, exquisite golden patterns or texts can be printed on book covers, greeting cards, etc.; hot stamping on film can be used for packaging materials to add a sense of luxury to the product; hot stamping on wood boards can make some textured crafts or furniture decorations; hot stamping on leather can create brand logos or decorative patterns on leather goods.

2. High pressure design

• High pressure is an important feature of this hot stamping machine. It can ensure that the hot stamping foil fits tightly with the hot stamped material, so that the pattern or text on the gold foil is completely and clearly transferred to the surface of the material. Whether on thicker wood boards or relatively soft leather, the gold foil can be compacted with sufficient pressure to ensure the hot stamping effect. For example, when hot stamping wood boards, high pressure can overcome the uneven surface of the wood boards and achieve uniform hot stamping.

3. Easy-to-operate relay panel

• The relay panel makes operation simple. Through the buttons or knobs on the panel, users can easily control the main functions of the hot stamping machine. For example, set the time, temperature and pressure of hot stamping. The use of relays enhances the control function of the circuit, and can accurately start and stop the hot stamping process according to the settings. Even non-professional operators can quickly master the operation method through simple training.

4. High cost performance

• This hot stamping machine has a high cost performance. It meets the needs of hot stamping of various materials such as paper, film, wood, leather, etc., and the price is relatively reasonable. Compared with some professional but expensive hot stamping equipment, it can provide basic hot stamping functions, and has good performance in ease of operation and wide range of applicable materials. For some small businesses or hand-made workshops, it is an economical choice that can meet the requirements of hot stamping operations while controlling costs.

|

Pneumatic hot stamping Machine //Structure |

||

|

Working table |

High strength Steel plate , size: 520*800mm. |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

Motor-drive , Collecting time adjustable |

|

|

Press adjustment |

Up-down of working table |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Foil collecting |

Motor drive, Automatically collecting |

|

|

Pneumatic hot stamping machine //Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

Pneumatic hot stamping Machine //Parameter |

||

|

Technical parameters |

H-TC233 |

H-TC234 |

|

1. Hot plate area:400×500 mm

8. Max Open distance: 150mm. |

1. Hot plate area:400×600 mm

8. Max Open distance: 150mm |

|

|

Works supply |

|

|

|

Package list |

|

|

|

||

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

Pneumatic hot stamping machine //Advantage |

||

|

Function |

|

|